How to buy a blister packaging?

Blister packaging: a general term for the production of plastic products by the blister process and packaging of the products with the corresponding equipment. Blister packaging products mainly include blister, tray, plastic box, synonym: vacuum cover, blister and so on. Blister pack equipment mainly includes a plastic molding machine, punching machine, sealing machine, high-frequency machine, folding machine. The packaged product formed by the package can be divided into the card, suction card, double bubble shell, half bulb shell, double folded bulb shell, three fold bulb shell and the like.

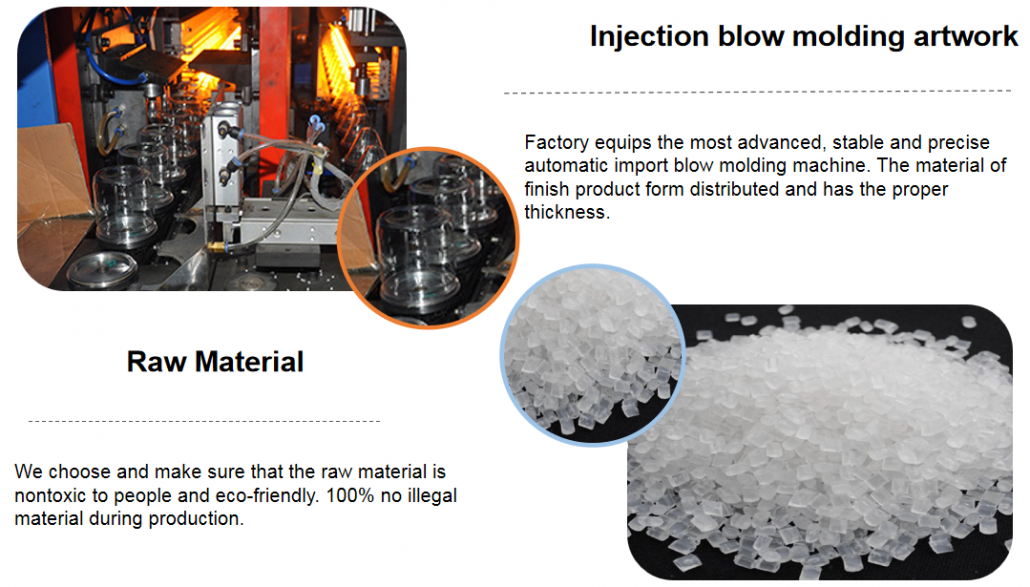

Blister: A plastic processing technology. The main principle is to heat and soften the flat plastic sheet. It is vacuum-adsorbed on the surface of the mold and cooled to form. It is widely used in plastic packaging, lighting, advertising, decoration, and other industries.

Bubble shell: The transparent plastic hard sheet is made into a transparent plastic with a specific convex shape by a blistering process, and covers the surface of the product to protect and beautify the product. Also known as a blister, vacuum cover.

Blister mold: mold for plastic production, the lowest cost is plaster mold, followed by electroplated copper mold, the most expensive is aluminum mold. The mold is drilled with small holes for vacuum adsorption of the heated hard sheets to form a blister product.

Blister molding: It is the blister that we often talk about. The plastic soft sheet that is softened by heating is absorbed on the surface of the mold by a plastic forming machine, and after cooling, plastic having a concave-convex shape is formed.

Blister cutting: plastic products after plastic forming, through the punching machine, the large sheets are cut into individual products by knife die.

Folding: The three sides of the blister are folded to the back with a folding mechanism so that in the next packaging process, the paper card is inserted into the hem to form a card package.

Heat sealing: It is a blister packaging process. The paper card coated with blister oil is heat-sealed together with a blister by a sealing machine to form a blister card package.

High-frequency sealing: It is a blister packaging process. A high-frequency machine is used to generate high-frequency, and the blister and the blister are bonded together to form a double blister package.

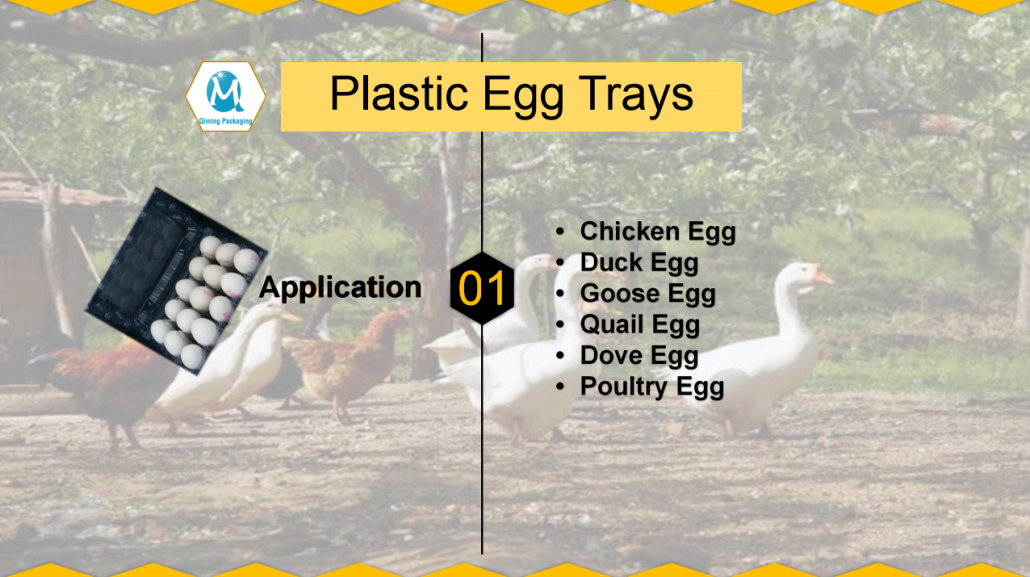

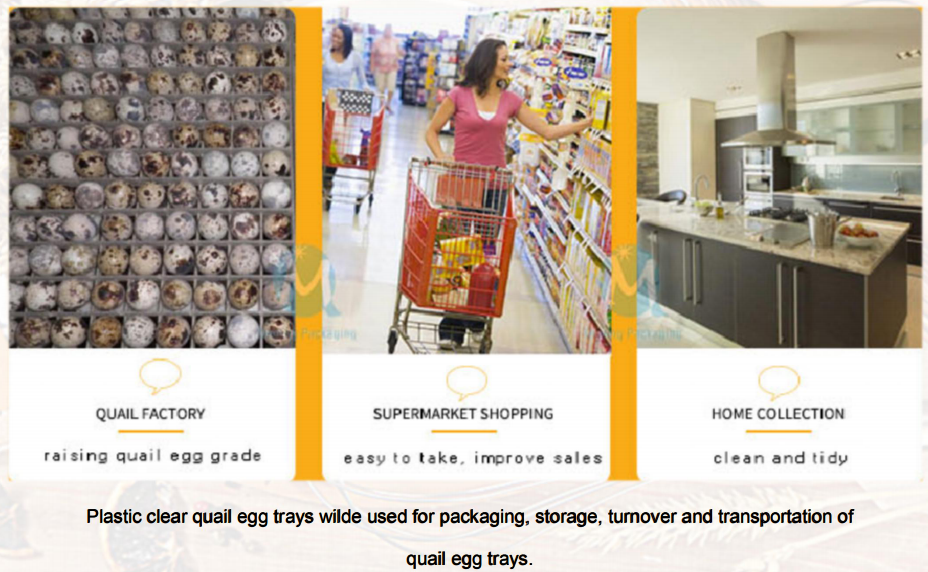

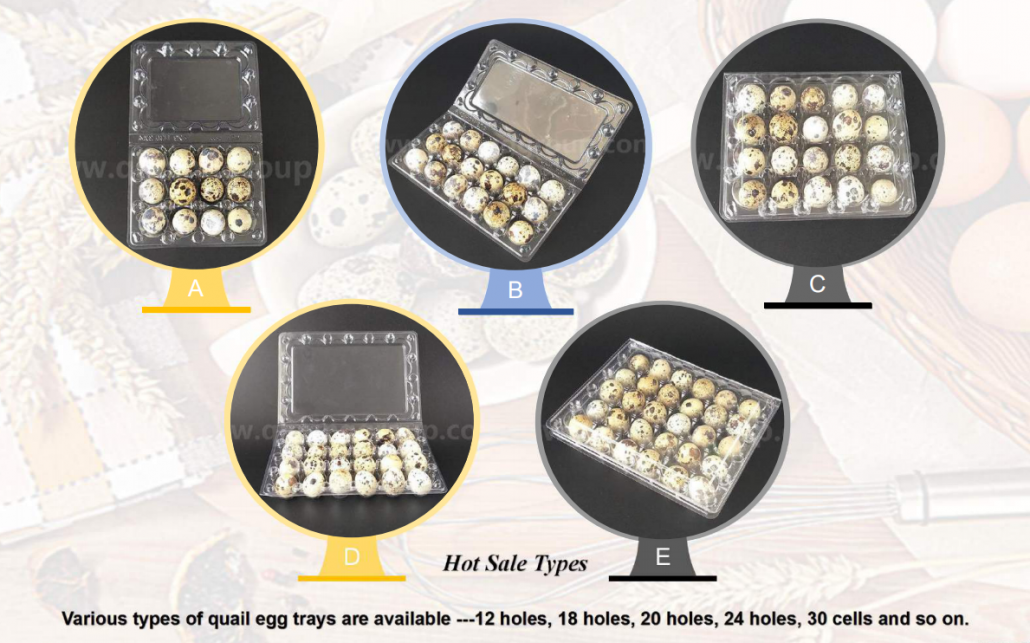

In our daily life, many products are made by blister processing, such as PVC transparent egg tray, quail blister egg tray, fruit tray and so on.

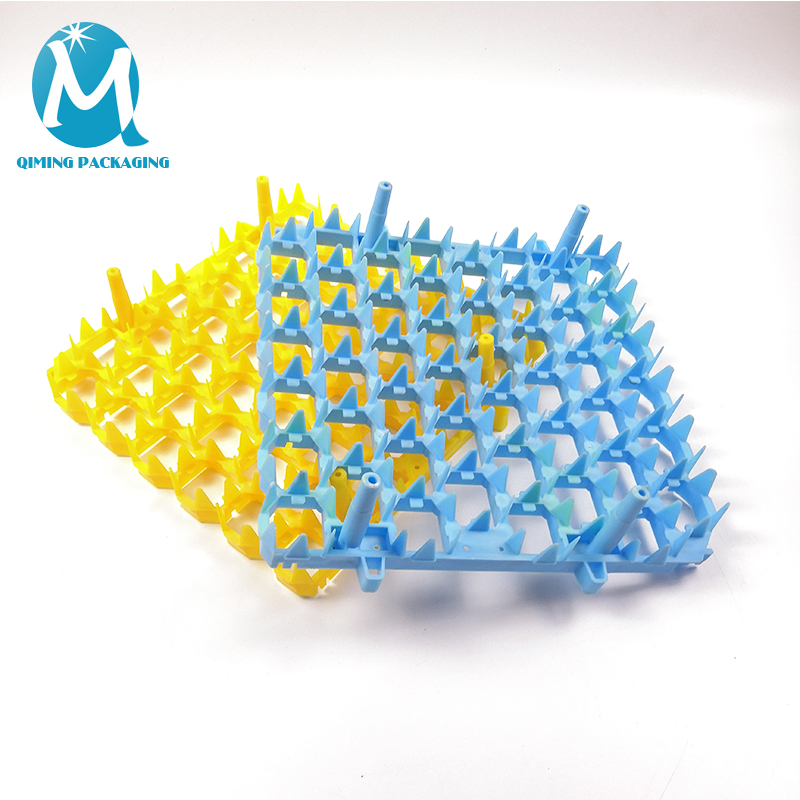

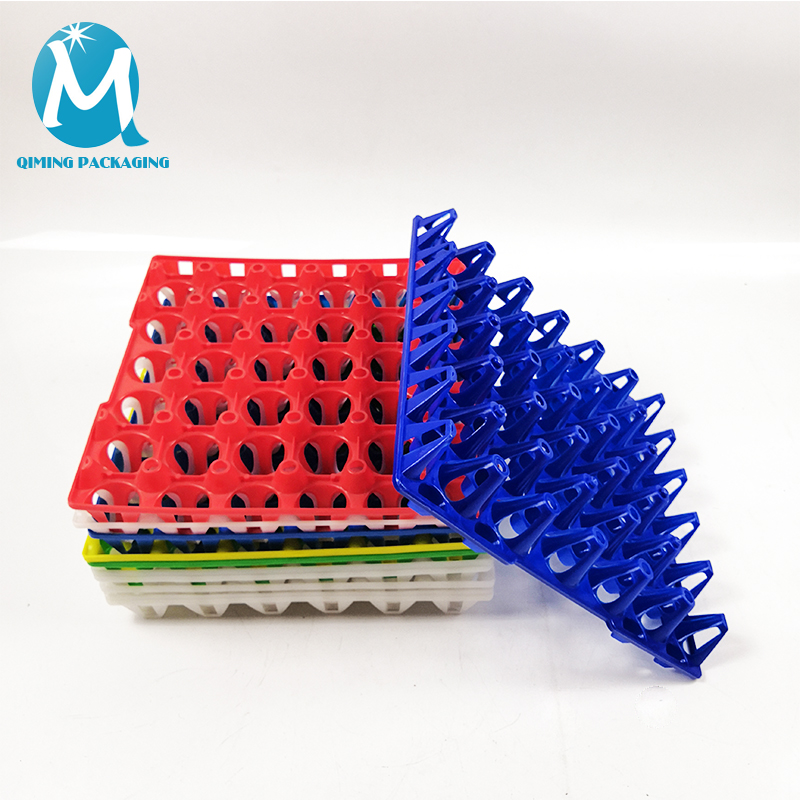

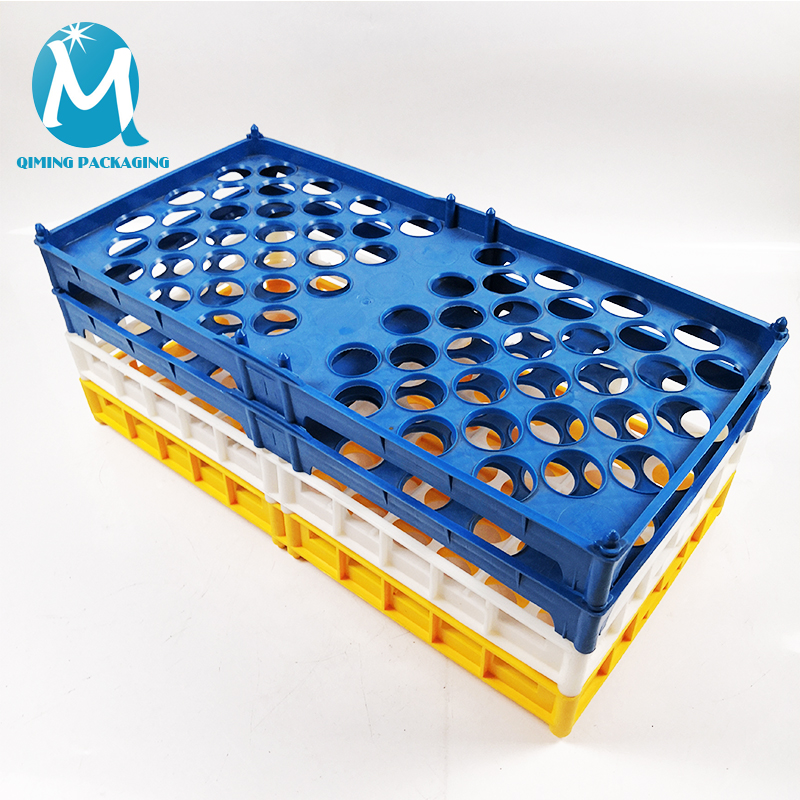

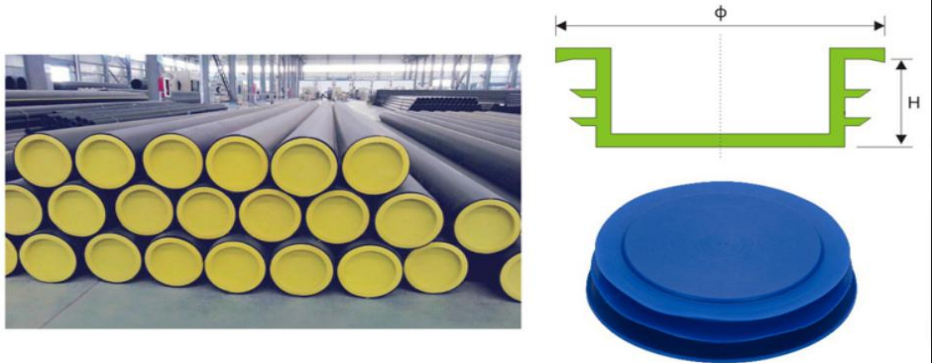

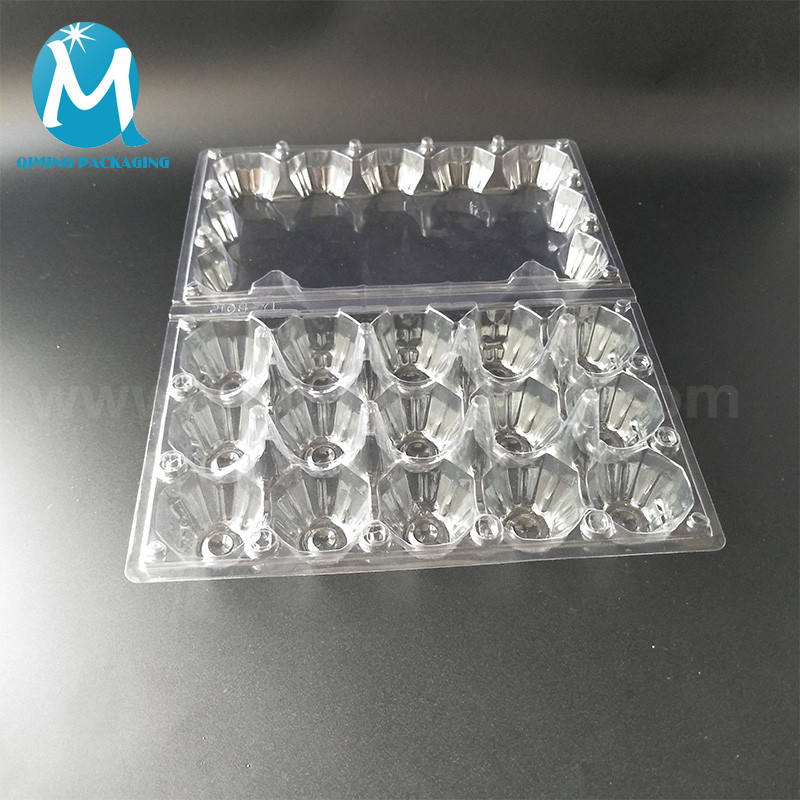

Product view of PVC blister egg trays-Blister Packaging

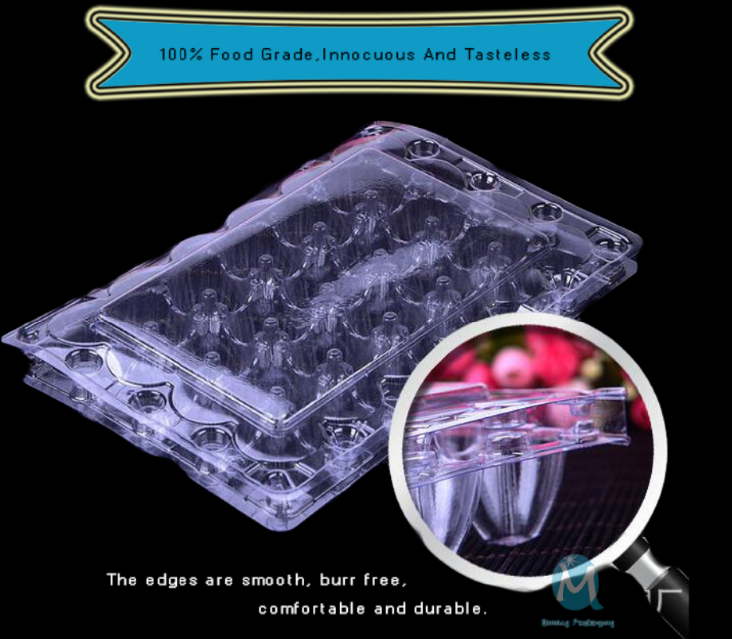

Some details about PVC blister quail egg trays

Available sizes to meet the different needs of the customers.

| Quail Egg Tray Type | Size Of Tray (L*W*H) | Size Of Hole (Diameter*H) |

| 12 cells (PVC) | 138*103*36mm | 29*36mm |

| 18 cells (PVC) | 198*103*36mm | 29*36mm |

| 20 cells (PVC) | 168*133*36mm | 29*36mm |

| 24 cells (PVC) | 198*133*36mm | 29*36mm |

| 30 cells (PVC) | 198*163*36mm | 29*36mm |

| 150 cells (PE) | 470*300*40mm | 15*6mm |

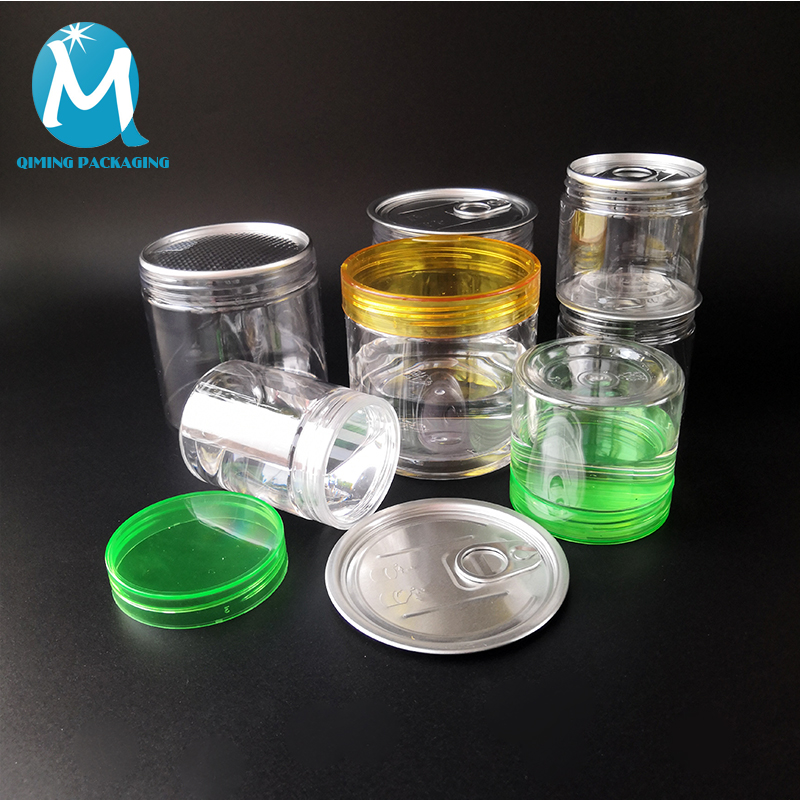

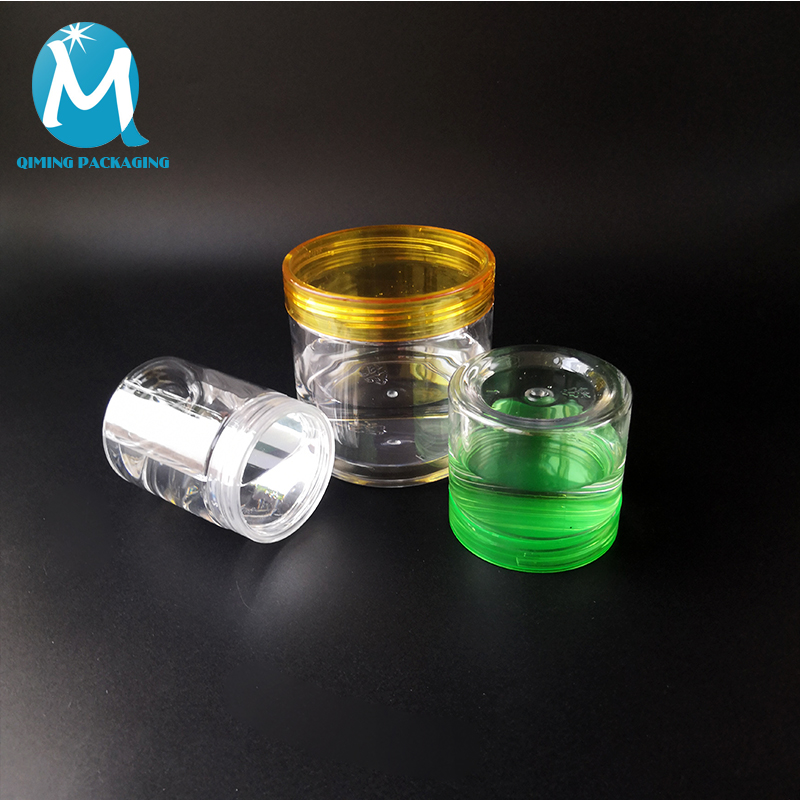

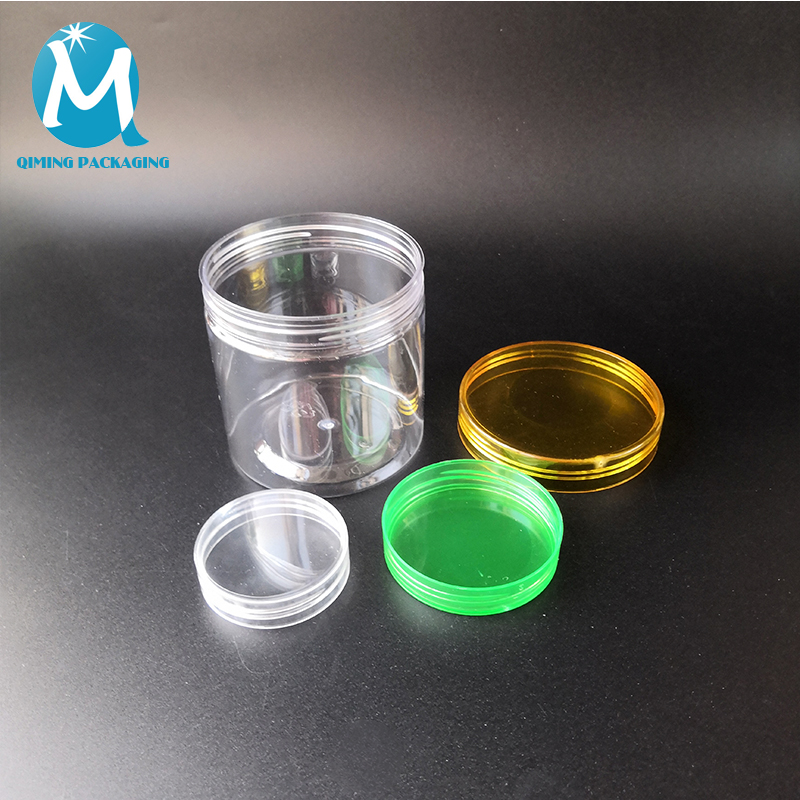

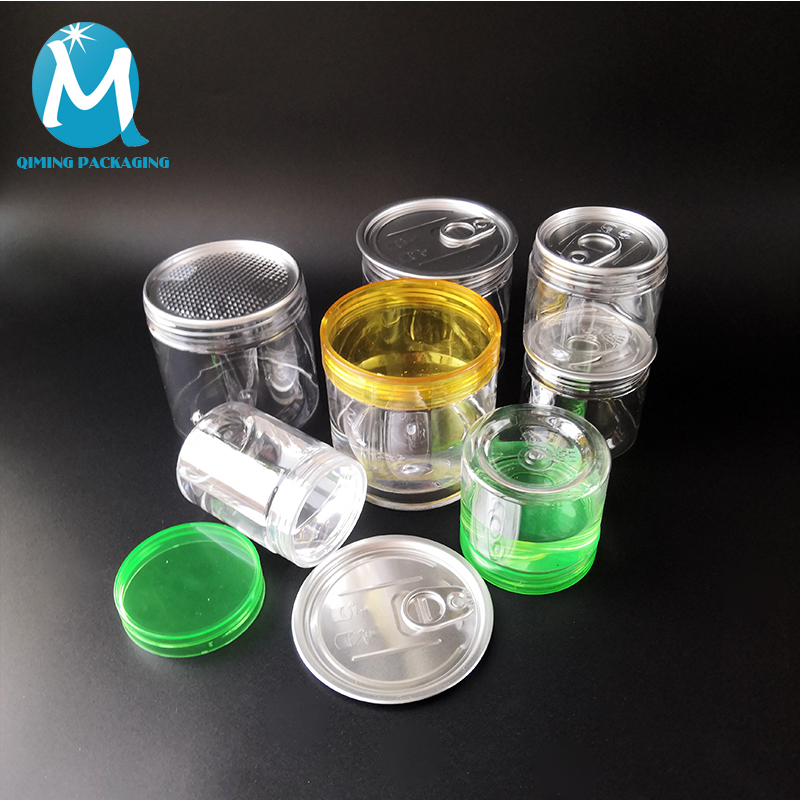

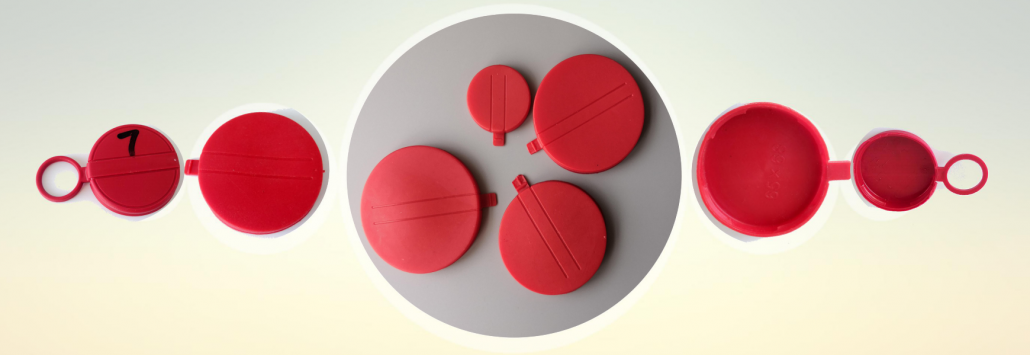

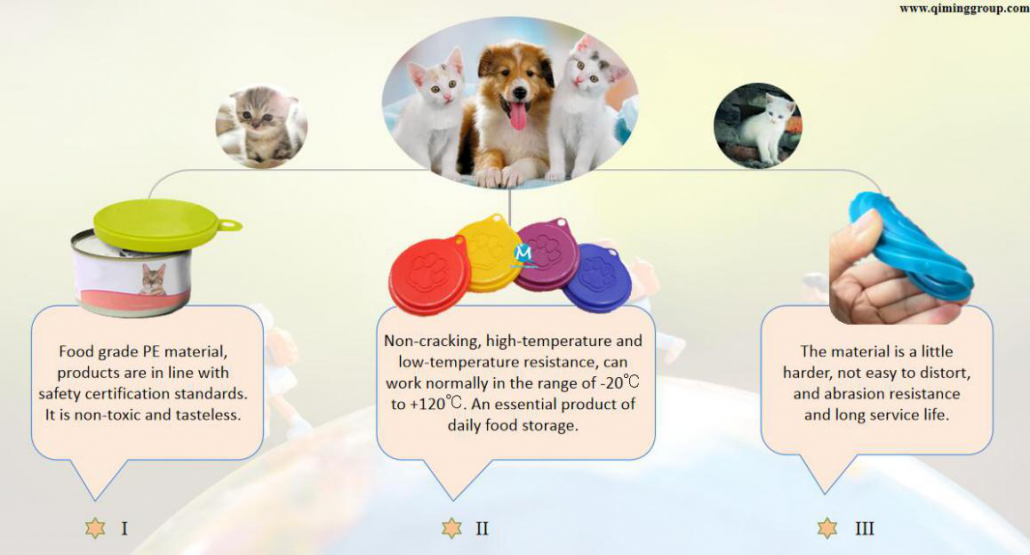

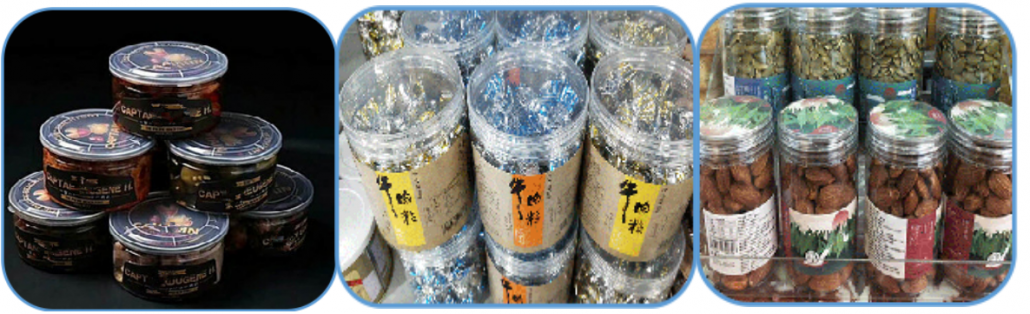

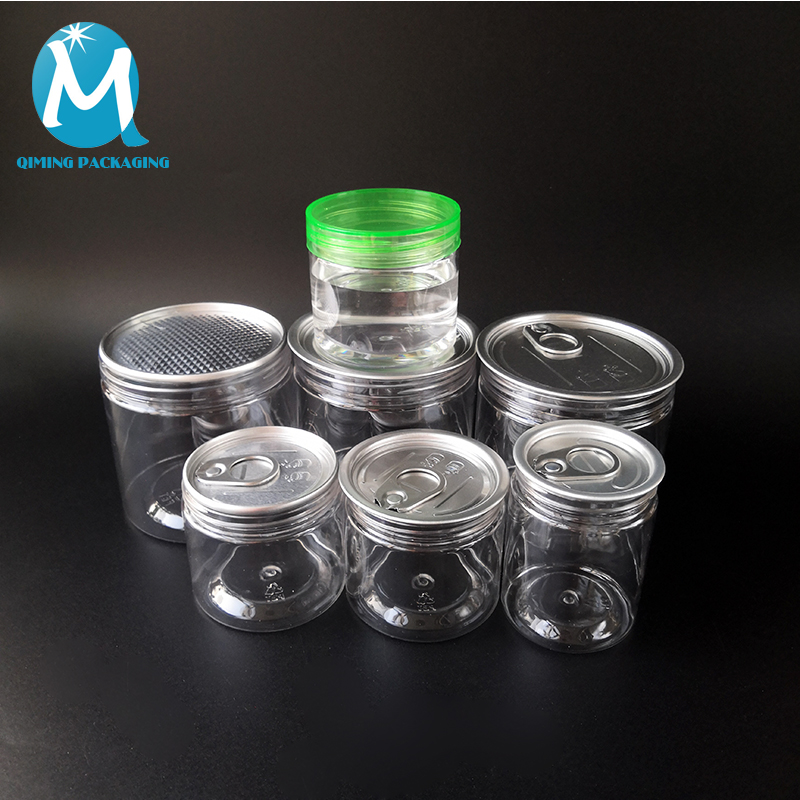

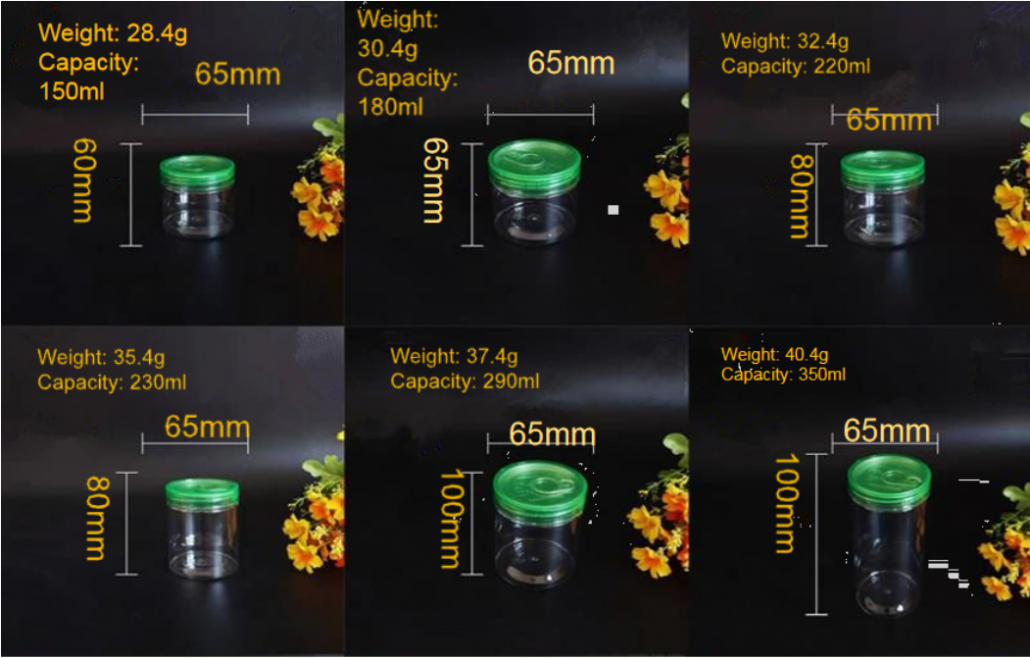

plastic containers

plastic containers