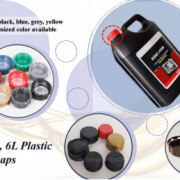

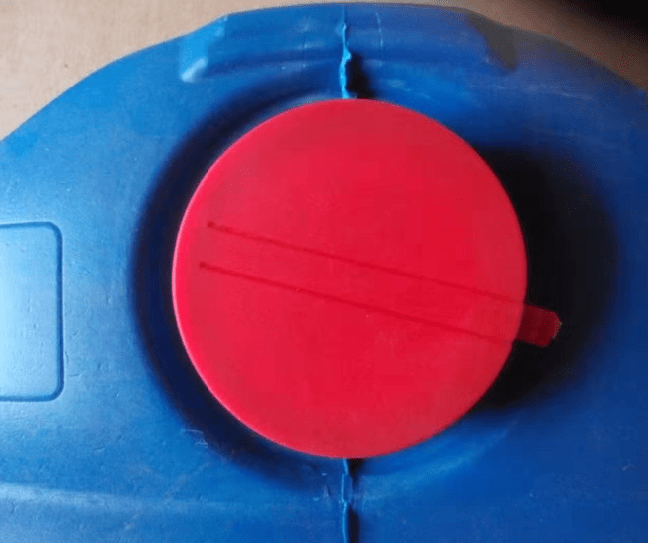

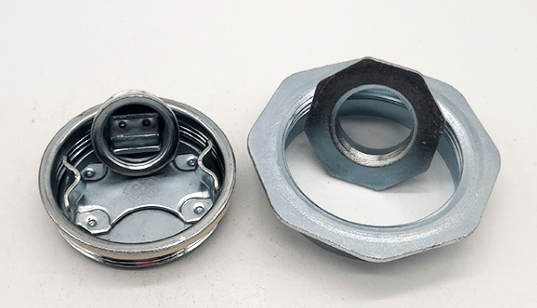

Plastic lids for Mobil engine oil bottle

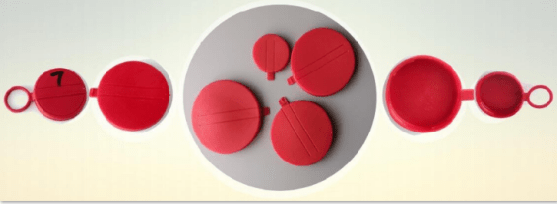

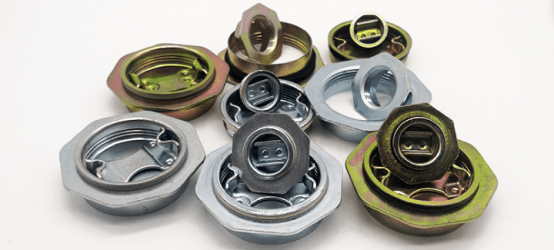

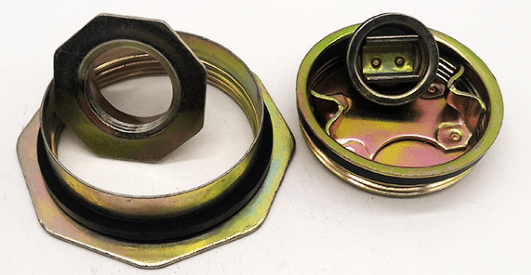

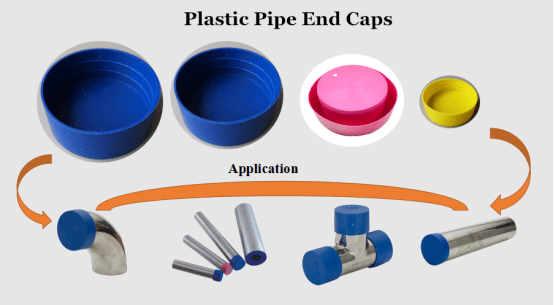

Plastic lids for mobil engine oil bottle-various kinds of plastic screw caps for drums, pails, buckets, cans, bottles, and pipes. Diameter 25mm- 300 mm.Customized logos available. HDPE, PE, PP, PE, the cap of a bottle or jar which screws onto the threaded lip of the container. A screw closure is a mechanical device which is screwed on and off of a “finish” on a container. Either continuous threads or lugs are used. It must be engineered to be cost-effective, to provide an effective seal (and barrier), to be compatible with the contents, to be easily opened by the consumer, often to be reclosable, and to comply with the product, package, and environmental laws and regulations. Some closures need to be tamper-resistant and have child-resistant packaging features.

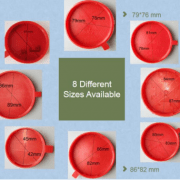

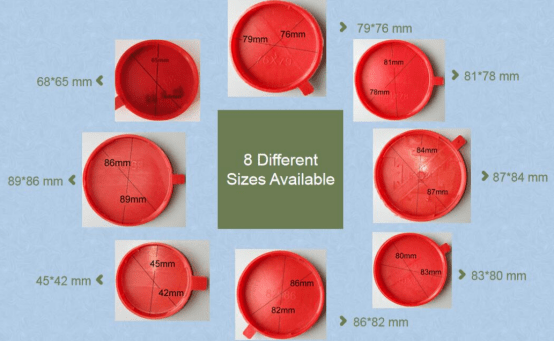

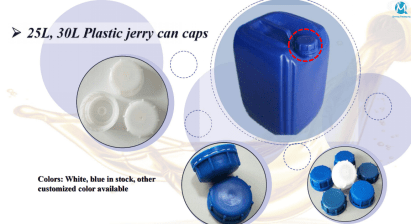

Plastic lids for engine oil bottle is the hot HDPE screw caps, various sizes are available, 25mm/29mm/30mm/34mm/36mm/38mm/39mm/43mm/46mm/48mm/49mm/55mm. They can be used for 1L/2L/4L/20L plastic Jerry cans, good sealing with aluminum foil.

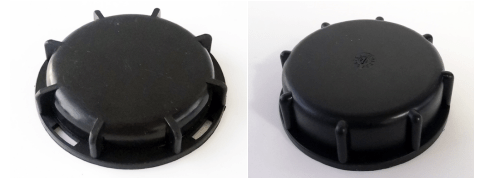

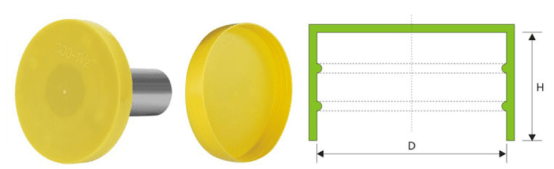

Specification of Plastic lids for Mobil engine oil bottle

-Material: PE

-Size Inner diameter: 35mm, 38mm, 43mm, 46mm, 55mm or customized size

-Color: White, blue or red and so on

-Packing: Carton+pallets

FREE samples available for you to check the quality and design if stocked. For your required new design, we could open a new mold for you when the quantity reaches our MOQ or certain quantity we both agreed with.

Are you looking for Plastic lids for the Mobil engine oil bottle? Qiming Packaging is a professional manufacture specializing in plastic lids, caps, covers for bottles, drums, buckets. If you are interested in such plastic caps, contact us today info@qiminggroup.com for a better solution now. We’d love to work with you together.

If you are not find the pruducts you want, you can click the another website: www.qimingpackaging.com. Or you can send the mail: mail@qiminggroup.com