Are plastic buckets safe for food?

Plastic buckets are mostly used for the storage and transportation of various products. They are not fragile, rust-free, light, and not easily deformed. They are also excellent in oil resistance and strong corrosion resistance. It is mostly used to hold liquid and solid objects in chemical raw materials, pesticides, lubricants, coatings, medicine, food, hardware and electronics, electromechanical and other industries. Specifications range from 100mL-40L.

Are plastic buckets safe for food? The answer is yes. The plastic buckets are made of 100% Virgin PP/PE material, not recycled material, so the material is pure, food grade. We have passed many food packing tests and applied for many food grade test reports and certificates of food standard approval. If the plastic bucket needs to be in direct contact with food, its production materials need to be issued by the manufacturer with a material inspection report to confirm that it is a food material before it can be used.

Below are some features of the food plastic bucket:

-Color selection: Multi colors are selectable, customized colors based on the big order quantity.

-Selection of plastic bucket materials: 1) Food grade, non-toxic, pollution-free, environmentally friendly, easy to degrade, suitable for food packaging. 2) Non-food grade, non-toxic, pollution-free, easy to degrade, untouched food, suitable for packaging of coating, glue, chemical products, and so on.

-Two types of printing terms: Silk-screen printing or Heat transfer printing available.

-Can be stacked for many layers, saving space and easy to take away.

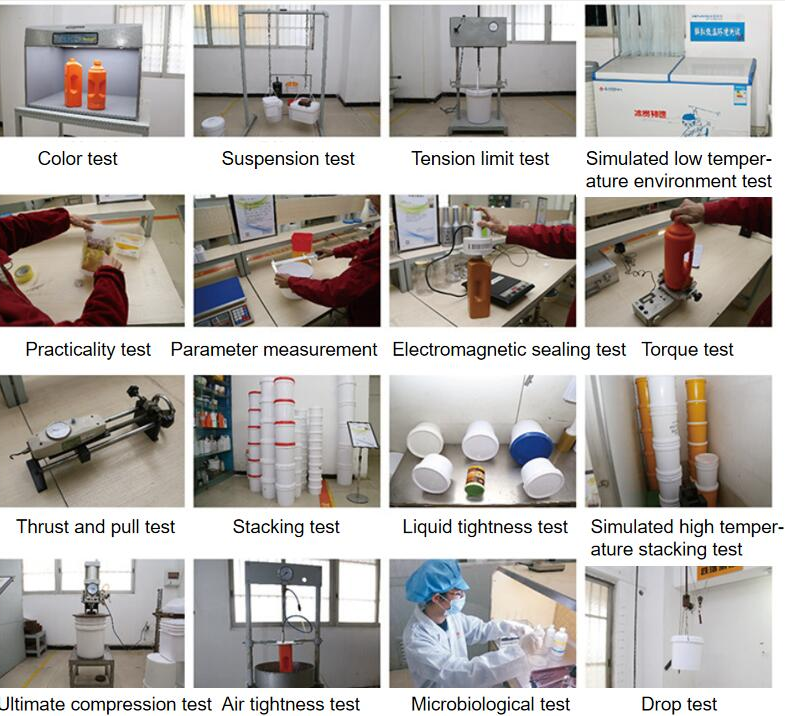

-Qiming Packaging provides the most complete testing items to ensure the quality and safety of the products so that the customers can rest assured.

Different sizes are for your options, show you the size list for the plastic buckets:

| Specification (L) | L*W*H(mm) | |

| 0.5 | 100*100*86 | |

| 0.8 | 115*115*115 | |

| 1 | 130*130*107 | |

| 1.1 | 130*130*106 | |

| 1.1 | 127*127*111.5 | |

| 2.1 | 155*155*143 | |

| 2.8 | 176*176*146 | |

| 3 | 156*156*191 | |

| 3 | 196*196*125 | |

| 3 | 177*177*177 | |

| 3.5 | 206*206*117 | |

| 6.3 | 210*210*210 | |

| 6.4 | 209*209*211 | |

| 8.8 | 223*223*252 | |

| 10.6 | 224*224*304 | |

| 12 | 253*253*285 | |

| 16 | 264*264*326 | |

| 18.5 | 264*264*361 | |

| 19.4 | 278*278*342 | |

| 20 | 280*280*375 | |

| 20(DEEP COVER) | 270(Top)*240(Bottom)*372(H) | |

| Custom sizes and colours |

| Specification | Top * Bottom * Height(cm) | Weight(kg) |

| 0.8L | 11*9.4*10.3 | 0.053 |

| 1L | 11.5*9.3*11.7 | 0.08 |

| 2L | 15.7*13.9*15.7 | 0.15 |

| 3L | 18.5*16.4*16.5 | 0.2 |

| 4L | 24.2*21.5*27 | 0.28 |

| 5L | 21*18.5*20.8 | 0.28 |

| short 5L | 23*21*18.5 | 0.33 |

| 6L | 21.7*19.5*21 | 0.338 |

| 9L | 24.5*21.5*24.5 | 0.495 |

| 10L | 25.8*23*27 | 0.56 |

| 15L | 28*25.5*31.5 | 0.71 |

| 16L | 28.5*25.5*31.5 | 0.72 |

| 18L | 30*26*36.3 | 0.95 |

| New Little 18L | 29.3*26.3*35 | 0.79 |

| New Little 20L | 29.5*26.5*36.5 | 0.895 |

| Double edge 20L | 30*26.5*38 | 1 |

| New 20L | 30.5*27*38 | 1.06 |

| Screw 20L | 30*27*37.5 | 0.933 |

| 25L | 32*28*39.2 | 1.145 |

| 30L | 33.5*29.5*42.8 | 1.530 |

| 40L | 35.4*31.7*37.9 | 2.43 |

| The above are only regular sizes, there are errors in manual measurement, please contact us for final product parameter confirmation. Accept the customized service of weight and size. |

Qiming Packaging is a professional manufacturer specializing in plastic packaging containers such as plastic buckets, pails, bottles, etc. They are widely used for packaging food, chemicals, paints, and so on. If you are interested in any type, please contact us at mail@qiminggroup.com for a prompt answer. We’d love to work with you together in the near future.

If you are interested in us, contact us now to get more detail!

Mobile/Whatsapp: 86-15324051286

Company email: mail@qiminggroup.com

round buckets pails with lids gamma buckets with lids

round buckets pails with lids gamma buckets with lids

Plastic Gym Wet Wipe Plastic Buckets Manufacturer Wholesale With Lids For SaleHot sale products

Plastic Gym Wet Wipe Plastic Buckets Manufacturer Wholesale With Lids For SaleHot sale products

metal drum cap seals for 210 litre drums-Qiming Packaging

metal drum cap seals for 210 litre drums-Qiming Packaging

PVC/UPVC/CPVC glue tin can, screw top round cans, cylinder metal tin cans

PVC/UPVC/CPVC glue tin can, screw top round cans, cylinder metal tin cans