At Qiming packaing, we take pride in presenting our high – quality custom rubber gaskets. These gaskets are designed to meet the diverse sealing needs of various industries, providing reliable and efficient performance.

Superior Materials

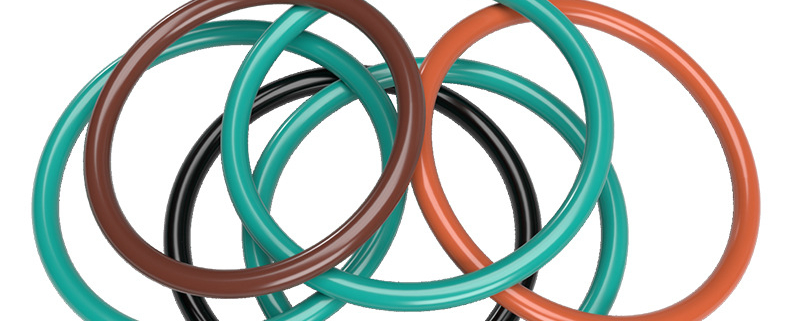

Our custom rubber gaskets are crafted from top – grade rubber materials. We offer a wide selection of rubber types, including but not limited to neoprene, silicone, EPDM, and nitrile. Each material has its unique properties, allowing us to customize the gaskets according to your specific requirements. For example, neoprene gaskets are known for their excellent resistance to oils, ozone, and weathering, making them suitable for outdoor applications. Silicone gaskets can withstand high and low temperatures, making them perfect for use in extreme thermal environments.

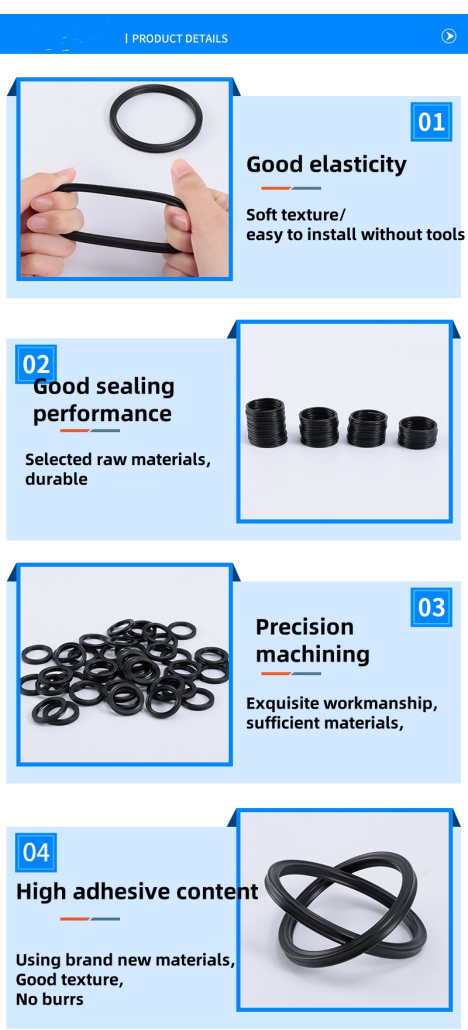

Product Details

| Size | Customized | Factory Location | HeBei | |

| Color | Customized | Package | 1000pcs per pp bag Carton box outside | |

| Shore Hardness | 30-90 Shore A | Certification | SGS;Rohs | |

| Material | Default Color | Temperture(℃) | Temperture(℉) | |

| Nitrile | Black | -30℃ - 100℃ | -22℉ - 212℉ | |

| HNBR | Black | -20℃ - 150℃ | -4℉ - 300℉ | |

| EPDM | Black | -55℃ - 150℃ | -67℉ - 300℉ | |

| Silicone | Red/White | -55℃ - 205℃ | -67℉ - 400℉ | |

| FKM/Viton | Brown/Green/Black | -20℃ - 200℃ | -4℉ - 392℉ | |

| CR | Black | -40℃ - 100℃ | -40℉ - 212℉ | |

| PU | Blue | -20℃ - 100℃ | -68℉ - 212℉ | |

| FFKM | Black | -20℃ - 320℃ | -68℉ - 572℉ | |

| AFLAS | Black | -30℃~230℃ | -86℉ - 446℉ | |

| FVMQ | White | -68℃~232℃ | -154℉ - 449℉ | |

| PTFE | White | -180℃~260ºC | -292℉ - 500℉ | |

| ACR | Black | -12℃~150℃ | -53℉ - 302℉ |

Customization Options

1. **Shape and Size**

– We understand that every application has different space constraints and sealing requirements. That’s why we offer custom – made gaskets in any shape and size. Whether you need a simple circular gasket or a complex multi – lobed shape, we can produce it with precision. Our advanced manufacturing techniques ensure that the dimensions of the gaskets are accurate to within very tight tolerances.

2. **Hardness and Density**

– The hardness and density of the rubber gasket can be adjusted according to your needs. A softer gasket may be required for applications where a tight seal is needed against irregular surfaces, while a harder gasket can provide better structural support in some cases. We can fine – tune these properties to ensure optimal performance in your particular application.

3. **Color Coding**

– For easy identification and organization, we also offer color – coding options for our custom rubber gaskets. You can choose a specific color for your gaskets, which can be helpful in differentiating between different types of gaskets used in a complex system.

Applications

Our custom rubber gaskets find applications in a wide range of industries:

1. **Automotive Industry**

– In cars, trucks, and other vehicles, our gaskets are used in engines, transmissions, and fuel systems. They help prevent leaks of fluids such as oil, coolant, and fuel, ensuring the proper functioning of the vehicle’s components and enhancing its overall reliability.

2. **Manufacturing and Machinery**

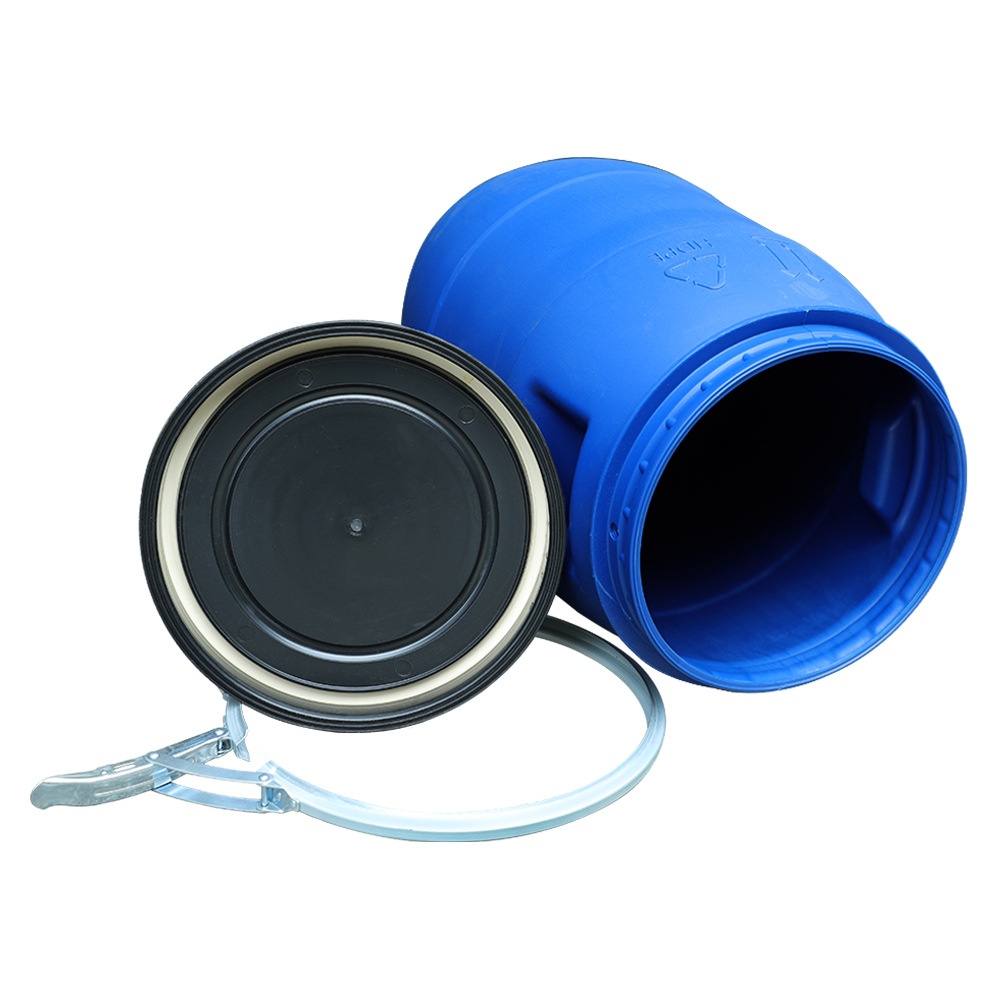

– Industrial machinery often requires effective sealing to prevent the ingress of dust, dirt, and moisture, as well as the leakage of lubricants and hydraulic fluids. Our custom gaskets are used in pumps, compressors, and various manufacturing equipment to maintain a clean and efficient operating environment.

3. **Construction and Plumbing**

– In the construction industry, our rubber gaskets are used in plumbing systems to create watertight seals in pipes and fittings. They are also used in building envelopes to prevent air leakage, improving energy efficiency in buildings.

4. **Electronics**

– In electronics manufacturing, our gaskets can provide EMI/RFI shielding as well as protect sensitive components from environmental factors such as moisture and dust. They are used in enclosures for computers, mobile phones, and other electronic devices.

Quality Assurance

1. **Stringent Testing**

– Every custom rubber gasket that leaves our facility undergoes rigorous testing. We test for factors such as sealing performance, durability, and resistance to environmental conditions. Our state – of – the – art testing equipment ensures that the gaskets meet the highest quality standards.

2. **TUV/ SGS/ Intertek Certification**

– We are an certified company, which means that our manufacturing processes adhere to international quality management standards. This gives you the confidence that you are receiving a product of the highest quality.

Customer Service

1. **Expert Technical Support**

– Our team of experienced engineers is available to provide technical support and advice. Whether you have questions about gasket selection, installation, or performance, we are here to help.

2. **Fast Turnaround Time**

– We understand the importance of timely delivery in your projects. That’s why we strive to offer a fast turnaround time for our custom rubber gaskets. Once we receive your order and specifications, we work efficiently to ensure that the gaskets are delivered to you as soon as possible.

If you are looking for a reliable, high – quality custom rubber gasket solution, look no further than [Qiming packaing]. Contact us today to discuss your requirements and let us create the perfect gasket for you.