A lotion-pump is a very common dispenser in everyday life. It can be found in the following areas: cleaning, washing, personal care, biomedical, foam emulsion, cosmetic packaging, chemical.

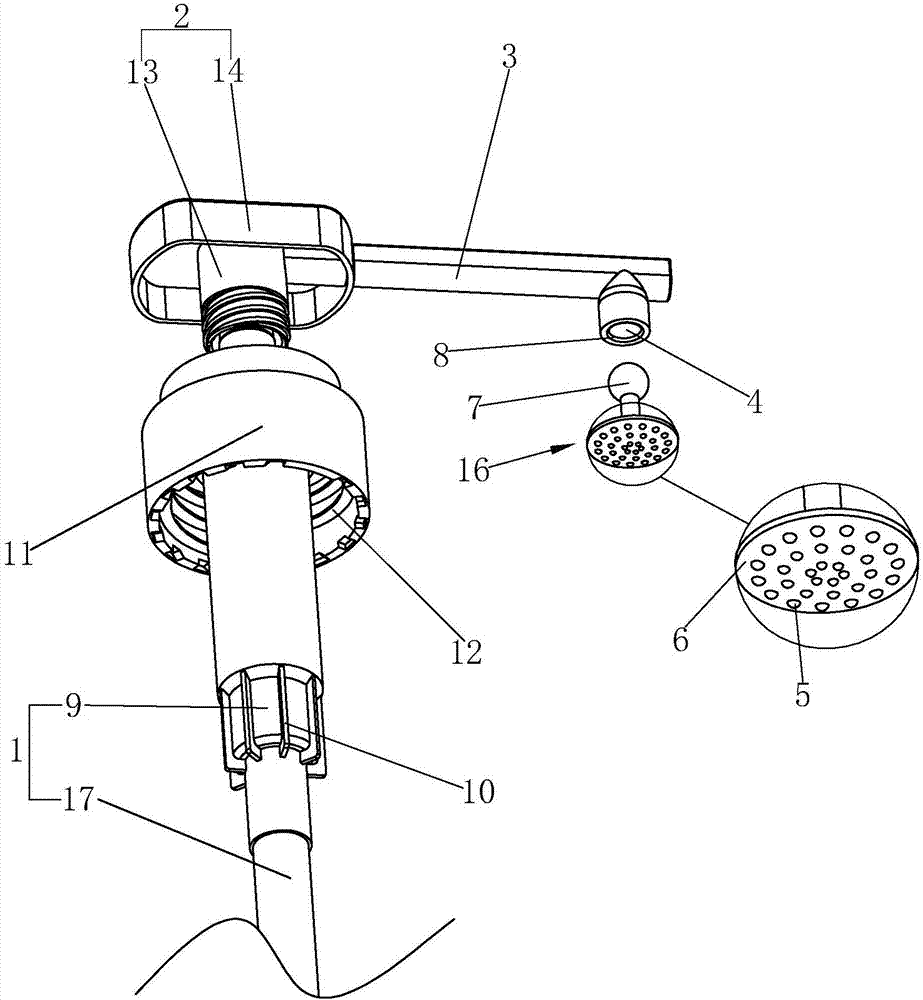

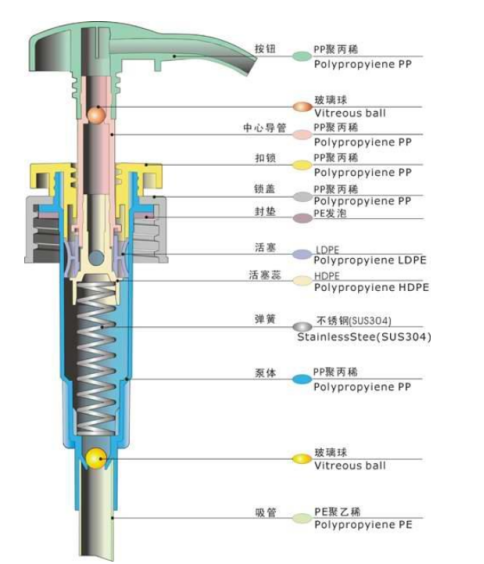

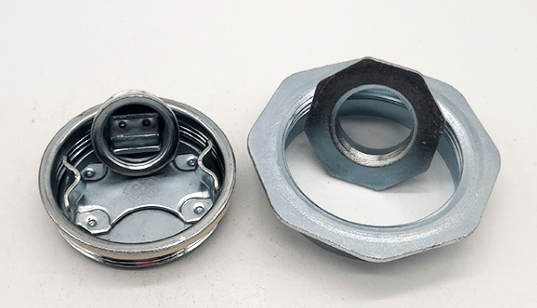

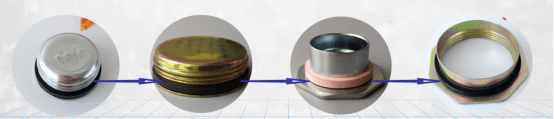

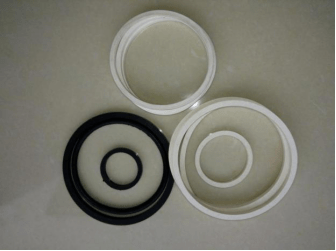

The dispenser is divided into two types, one is the latch type and the other is the screw type, and the other is the spray, foundation cream, lotion-pump, aerosol valve, and vacuum bottle. The composition of the dispenser is more complicated, generally includes press button, press button, gasket, piston, spring, valve, cap, pump body, suction tube, and valve ball (with steel ball, glass ball). Caps, dust caps can be tinted, electroplated, can be set with an aluminum ring.

Next, we Qiming Packaging take you through the Lotion pump.

1.Basic Information Of Lotion Pump

Lotion-pump is a kind of liquid dispenser that uses the principle of atmospheric equilibrium to pump out the liquid from the bottle by pressing and replenishes the atmosphere from outside into the bottle. The main performance indicators of the lotion pump: the number of air pressure, pump output, downforce, opening torque of the press head, rebound speed, water intake index, etc.

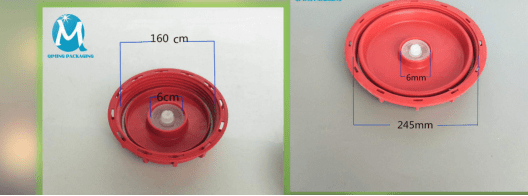

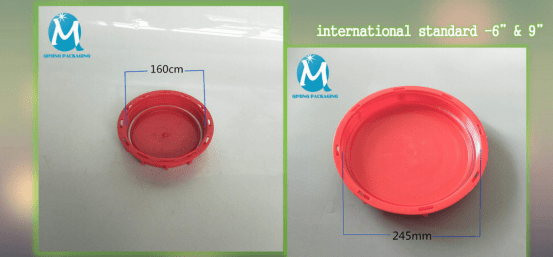

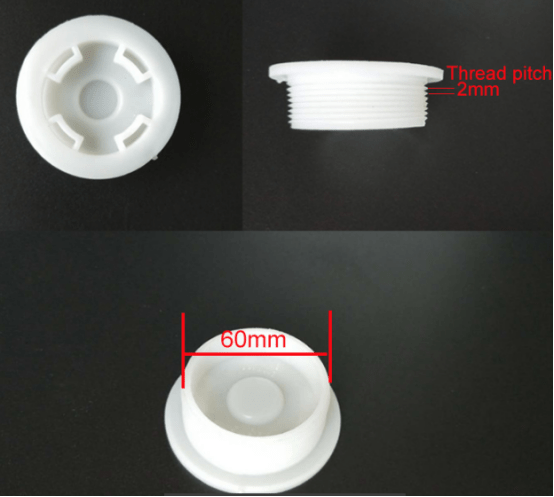

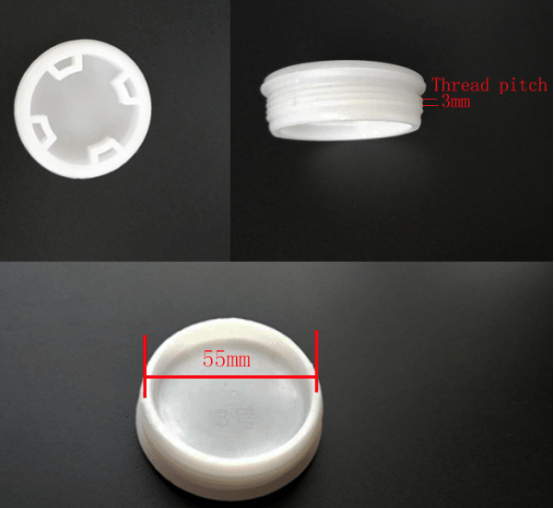

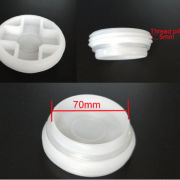

The size of the pump head is determined by the caliber of the matching bottle, the size of the spray 12.5mm-24mm, the water output is 0.1ml/time – 0.2ml/time, generally used for perfume, gel water, and other products on the packaging for use, the same caliber pipe length can be determined by the height of the bottle.

Lotion-pump head size range is larger from 16ml to 38ml, water output is 0.28ml/time – 3.1ml/time, generally used for creams and washing products.

Special dispensers such as Plastic Foam Pump Head and Hand Buckle Nozzle, the foam pump head is a non-inflating hand-pressure pump head that does not need to be inflated to produce foam, just press lightly to produce quantitative high-quality foam. Generally it comes with a dedicated bottle. The hand-button nozzle is usually used on products such as cleaning agents.

2.Working Principle Of The Lotion Pump Head.

Manual downward pressure shank, the volume in the spring cavity is reduced, the pressure rises, the liquid through the hole in the valve spool into the nozzle cavity, and then through the nozzle outward spray liquid, then release the pressure shank, the volume in the spring cavity increases, the formation of negative pressure, the sphere is opened under negative pressure, the bottle of liquid into the spring cavity, then the valve body has a good amount of liquid, when the pressure shank again when the liquid stored in the valve body will be pushed upward, through the nozzle outward spray.

3.The Key Points Of A Good Lotion Pump Head

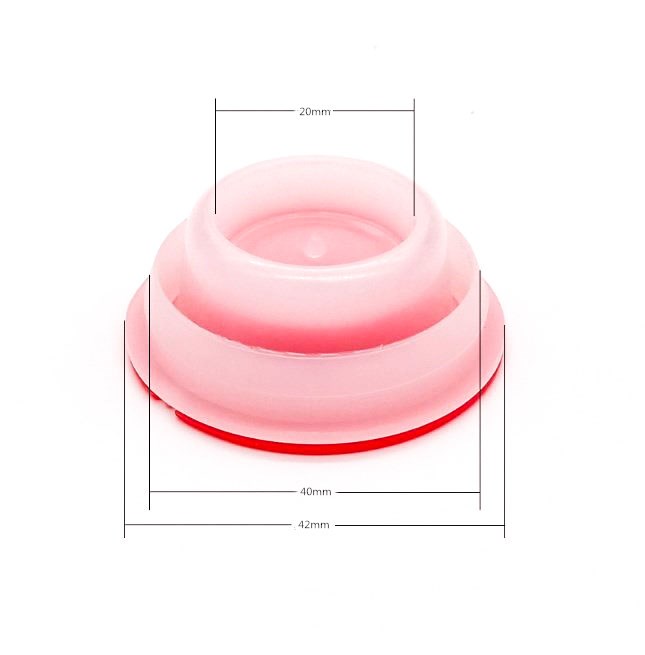

From the above working principle, Qiming Packaging suggests you a good lotion pump head key in the following places pay special attention to: 1, the spring under the glass or steel beads, here the seal is very important, related to the spring cavity in the liquid up the strength of the punch, if the leak here when you press the pressure stem when the liquid will have part of the leak to the inside of the bottle and affect the effect of the liquid to the outside spray; 2, is the upper part of the valve body seal, here if the leak, when the pressure stem release when the liquid up the bottom of the lotion pumping force is reduced, resulting in the valve body stored liquid amount is small, it will also affect the spray effect; 3, the pressure stem and spool at the cooperation, here with if there is loose leakage, when the liquid up the nozzle will have some resistance, the liquid will flow back, if the leak here will also affect the spray effect; 4, the nozzle design of the lotion pump, nozzle design is directly related to the spray effect.

So the general function of the lotion pump head is also to detect these four positions, other cosmetic and fit problems are routinely detected.

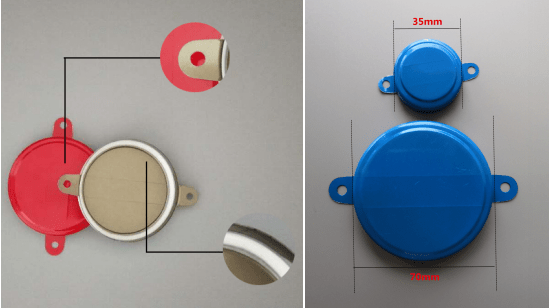

4. Lotion Pump Feature From Qiming Packaging

- Designed to prevent liquid leakage

- Good spring material, stainless steel 304H

- The spray is uniform and the effect is good.

- It is easy to use, effortless, and easy to press.

- Economy and durability

- Good sealing to prevent liquid leakage

- A variety of specifications can match more bottle bodies

- Screw off the pump head when it is not used or carried, and turn it clockwise to this state to prevent leakage

- When using, as shown by the arrow, rotate the pump head anticlockwise to press out the liquid

Maybe you’re still skeptical or comparing among lotion pumps, How about asking for a sample to see the quality? We Qiming Packaging offers FREE samples for quality testing. Contact us now. Maybe you’ll get free shipping today.

If you are interested in us, you can contact us: mail@qiminggroup.com/lynettelian@qiminggroup.com/Whatsapp/Wechat: +8615324051286