Logo Printed Cap Seal Manufacturer

Plastic chemical barrels, also known as plastic chemical barrels, is the use of the scientific formula of blow molding. It has many colors, beautiful and generous in appearance. It achieves the packaging index in acid and alkali resistance, corrosion resistance, leakage prevention, does not fade, does not deformation, and other aspects. It is an ideal choice of the chemical products packaging materials long-distance transportation. Today we will introduce Logo Printed Cap Seal Manufacturer for you.

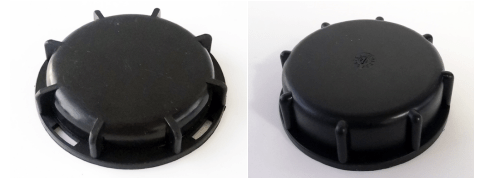

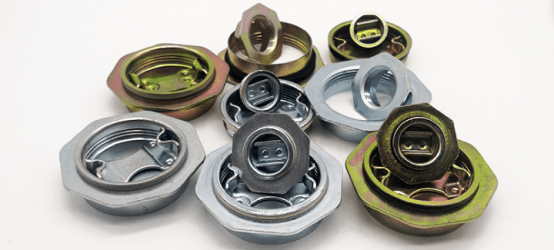

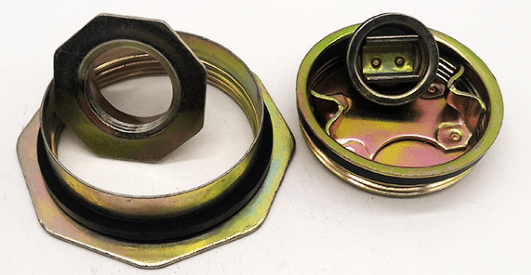

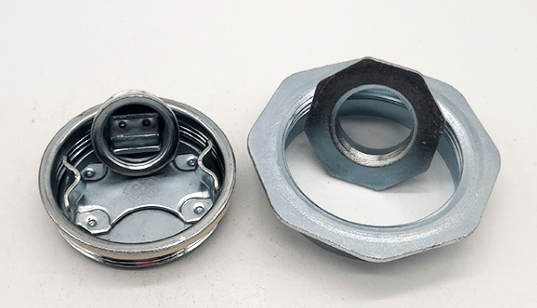

The 200l iron barrel cover is made of stamping with a high-quality cold plate, and the technology of rolling wire, spot welding, and galvanizing are completed.

Material: Prime Tinplate (0.22mm thickness)

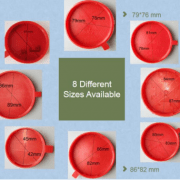

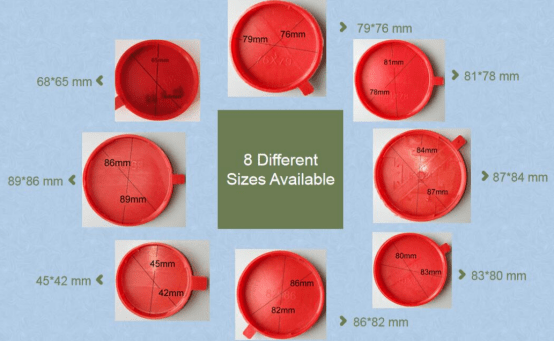

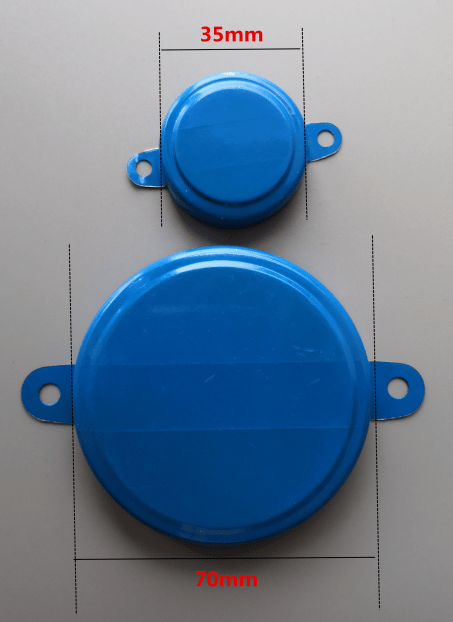

Size:2 inch and 3/4 inch (70mm and 35mm)

– 2″ (50 mm) plug – cap seal outer diameter 70 mm

– 3/4″ (19mm) plug – cap seal outer diameter 35 mm

Feature: Anti-theft and tamper-proof function tinplate drum cap seals wholesale

Function: Waterproof and theft-proof

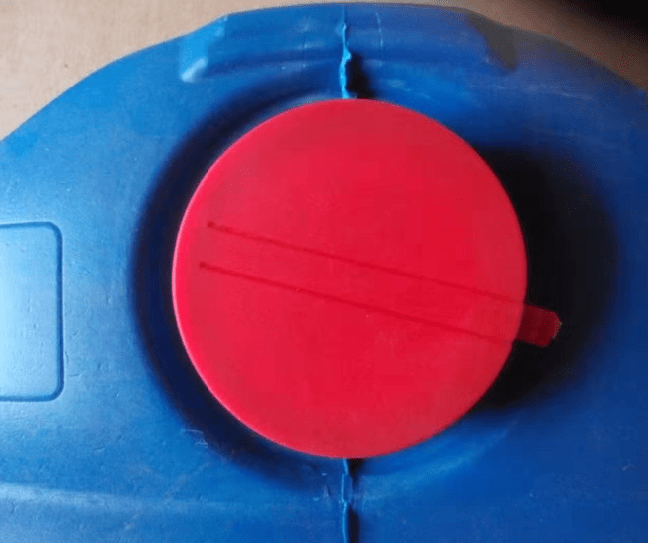

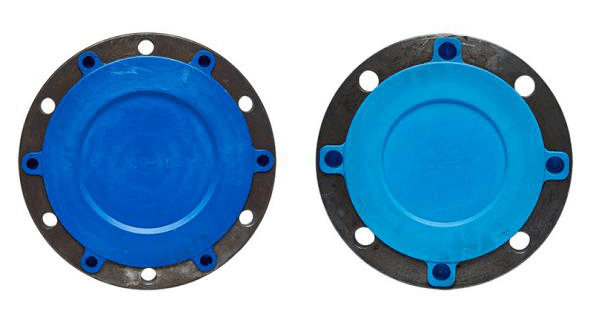

Application: Mainly used for 200L oil drums, protect against pilferage or substitution of drums’ contents.

Metal cap seals are installed with a crimping tool that secures the drum’s openings from any tampering.

Quick Details:

Material: Metal, Tinplate

Metal Type: Tinplate

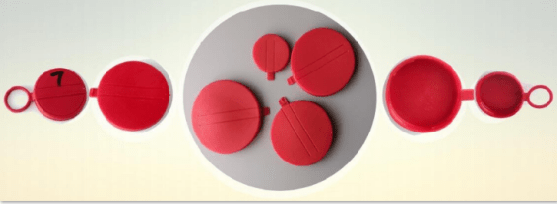

Type: Smart Lids, sealing cap security cap

Usage: Cans, 55 gallon, and 210L steel drums oil drums

Feature: Pilfer-Proof

Custom Order: Accept, Accepted

Place of Origin: Hebei, China

Brand Name: Qiming, Qiming

Model Number: LYQg037

Free Samples: Accepted

MOQ: 10000pcs

Product name: 2″ and 3/4″drum cap seal competitive price tinplate drum cap seal

Diameter: 2 inches and 3/4 inch (70mm and 35 mm)

Packing way: Strong Carton+woven bags +Plastic Pallet

Tangshan Qiming Trade Co., Ltd.

known as “Qiming Packaging”, Qiming Packaging is a professional engaged in the research, development, sale, and service of packaging and printing products.

If you would like to know more about our Logo Printed Cap Seal Manufacturer, plastic plugs, covers, or tinplate cap seals, you could also contact us by email or calling us to know more. (info@qiminggroup.com)

Qiming Packaging Pack Your More Safety Life!