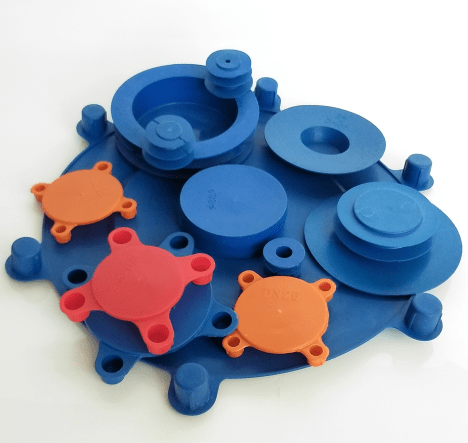

Plastic end caps for copper pipe

How to choose a good plastic end caps for copper pipe:

1.look – the appearance of unqualified products will affect the visual perception of consumers. At the same time, the appearance is a reflection of the internal quality. The appearance of unqualified products has poor internal quality and affects the user experience. If the product appearance is rough, having forming defects, color impurities, printing quality is poor, it is better not to choose.

2. Smell — it is better not to use the product that has odors. The pungent odor will harm the human respiratory system. The main reason plastic products have odors is the use of recycled materials and inferior additives.

3. Touch – In order to catch the eye of consumers, the color of the product is very bright. But how to check the product in good quality or not ? For example, if you check a product in a dark color or the pigment in the process of producing, you can just check it by yourself. Pour a little vinegar on the wool ball and wipe the face to 100 times repeatedly again. If the wool ball is dyed with color, it shows that his product is unqualified.

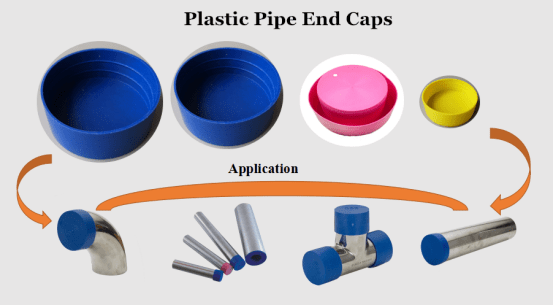

The applications and the development of the plastic end caps for copper pipe:

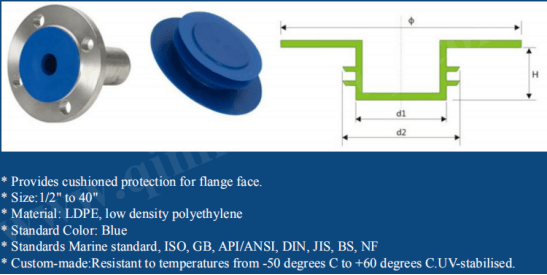

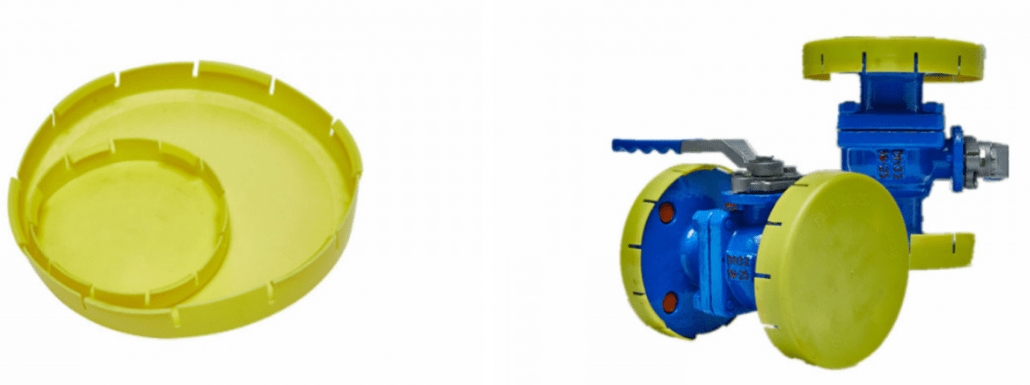

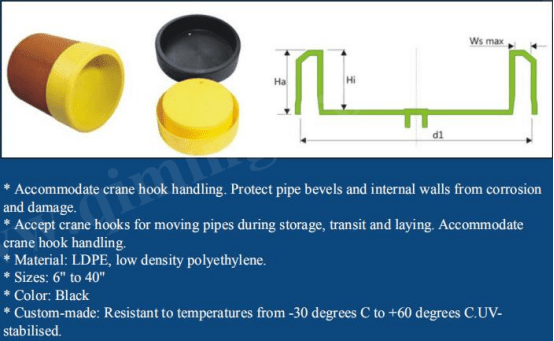

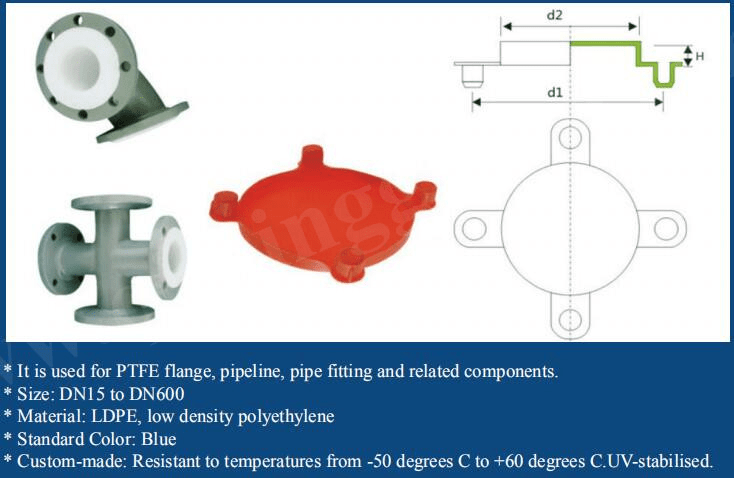

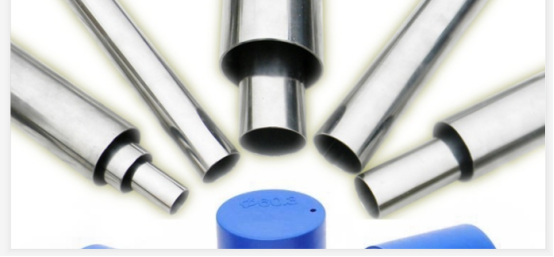

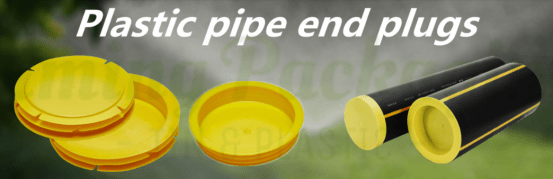

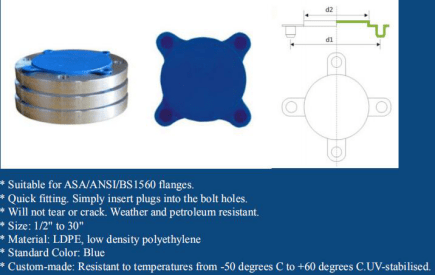

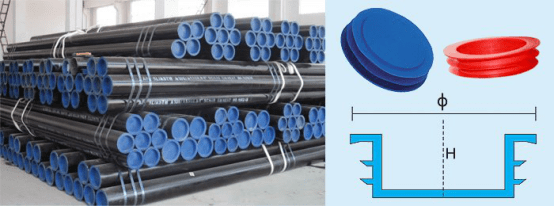

Welded on the pipe end or installed on the external thread of the pipe end to cover the pipe fittings that block the pipe. It is used to close the pipeline and has the same function as the pipe block.

Plastic pipe caps are made of plastic as the main raw material, and the development direction of plastics can be summarized in two aspects. One is to improve performance, that is, to modify existing varieties by various methods to improve its comprehensive performance; second, to develop functions, that is, to develop polymer materials with physical functions such as light, electricity, and magnetism so that plastics can have Photoelectric effect, thermoelectric effect, piezoelectric effect, etc.

If you are interested in us, contact us now to get more detail! If you do not find the products you want, you can click another website: www.qimingpackaging.com. Or you can send the mail: mail@qiminggroup.com