How To Select The Correct Capseals For Drums?

Basic analysis and Suggestions

How To Select The Correct Capseals For Drums?Drum bung cap seals are more and more important in the packaging industry for drums .General speaking,in order to find correct 2 inch and 3/4 inch drum bung capseals ,you need to confirm your drum bung type and size firstly .To be specific, followings are basic as well as important tips.

—How To Select The Correct Capseals For Drums?–What Is Capseals For Drums?

Drum bung capseals are lightweight metal or plastic caps which crimp over the bung openings of drums with a sealing tool. To remove them, they must be destroyed, that is also why it is easy to tell if tampering has occurred. Qiming Packaging offers a complete line of drum bung capseals for steel and plastic drums either in tinplate or plastic. Following pictures are the most popular styles from us. For other types ,please write to our support team by email mail@qiminggroup.com.

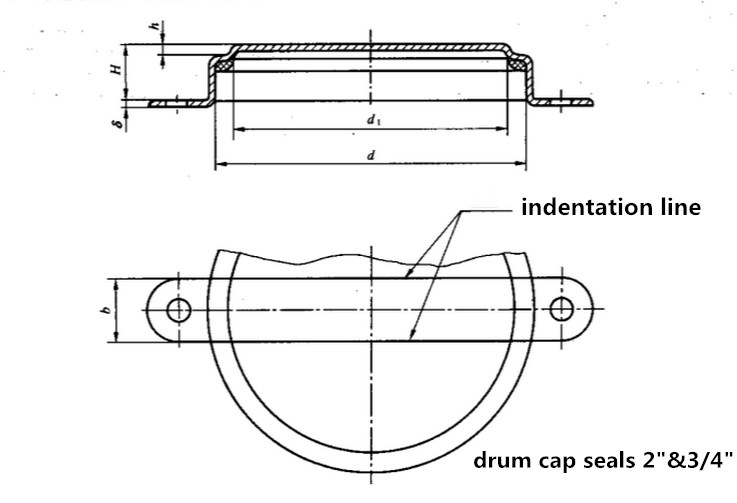

Just the technical drawing and data for your reference . For more information and customized service ,please contact us freely any time. We assure you any relevant inquiry will get our fast attention soon !

| Drum Metal Cap Seals -Qiming Packaging | |||||

|---|---|---|---|---|---|

| Item | d | d 1 | H | h | δ |

| G2 Cap Seal | 69.40 | 63.00 | 11.00 | 2.50 | 0.28 |

| G3/4 Cap Seal | |||||

| All the units in millimetre (mm)-Free Samples available for quality checking |

—How To Select The Correct Capseals For Drums?–Main Function Of Drum Bung Capseal

For added protection against tampering ,leakage and rain-proof , we offer a choice of cap seals as a final drum closure component. All of our cap seal designs are suitable for virtually any packaged product.

The metal tamper evident Drum Bung Cap Seals with flowed-in gaskets(you may called washer) are the most efficient commercial sealing device developed to protect the goods in drums.

—How To Select The Correct Capseals For Drums?—Size And Application

All of our drum bung cap seals are available in 2 inch and 3/4 inch and are designed to fit steel drums with a round bung.They are available in any color and your required logo .At the same time,our drum bung cap seals also fit a few plastic and fiber drums. Upon drums are filled, drum bung cap seals are screwed in the flanges using pneumatic or hand operated bung tightener or torque wrench. To secure the contents of the drums against theft and adulteration during shipment, that is why drum bung cap seals are applied . These drum bung cap seals sit on top of the flanges and are ‘crimped’ using drum cap seal crimping tools (also named drum cap sealers). Once drum bung cap seals are crimped, the plugs or bungs can be unscrewed only by breaking these drum bung cap seals .

—How To Select The Correct Capseals For Drums?–Material Type

We supply Two different materials of drum bung cap seals fit your different drums’ requirements.

- Material:Tinplate . Thickness of tinplate are optional from 0.2 mm to 0.35 mm. Drum cap sealing tool needed .various colors available .Logo application available. Strong evident drum bung cap seals.

- Material:Plastic .PE(PE Polyethylene).No crimping tool required ,ease of application .Chemically resistant ,recyclable plastic and lower cost ,various colors available .Logo application available.

—Choose Qiming Packaging and Find Correct Capseals Now

Above are just some basic tips to find suitable 2 Inch and 3/4 Inch drum bung cap seals for your reference. Qiming Pacakging in the business of manufacturing and marketing drum bung cap seals for steel drums and plastic drums .Three plastic styles in stock can be applied to drums without the use of a crimping tools ,three tinplate styles in stock also available .Any color and logo is acceptable . Contact us for a FREE sample sending and pricing information today!

The People Who Like This Post Also Read The Followings

twist off metal lids

twist off metal lids