Versatile Protection: Steel Drum Closures for Diverse Storage Needs

In industries ranging from chemicals to pharmaceuticals, agriculture to food processing, the safe and secure storage of products is paramount. One of the critical components ensuring this safety is the humble yet vital steel drum closure. Often overlooked, these closures play a significant role in maintaining the integrity of the contents within steel drums, offering versatile protection for diverse storage needs. Here’s why steel drum closures are essential and how they cater to various industry demands.

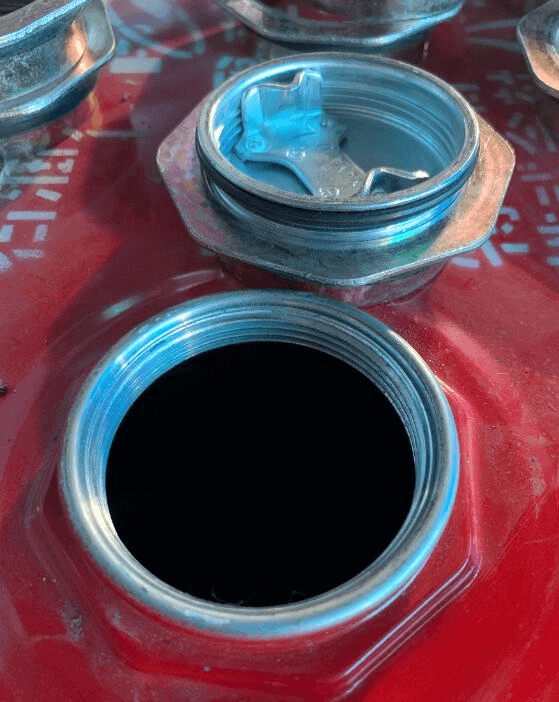

Steel drums are widely recognized for their strength, durability, and ability to store a wide array of products, from hazardous chemicals to food-grade materials. However, the effectiveness of a steel drum is largely dependent on the quality of its closure. A well-designed steel drum closure ensures that the drum remains leak-proof, tamper-evident, and resistant to environmental factors, such as moisture, heat, and contaminants. In essence, the closure is the final line of defense, preserving the quality and safety of the drum’s contents.

Tailored for Diverse Applications

Steel drum closures come in various designs, materials, and sizes, making them adaptable to different industry requirements. For instance, in the chemical industry, where drums often store volatile or hazardous substances, closures must be exceptionally secure to prevent leaks and withstand the corrosive nature of the contents. On the other hand, in the food and beverage industry, closures must ensure that products remain uncontaminated and fresh over extended periods. This adaptability makes steel drum closures a versatile solution for a wide range of storage needs.

Key Features of Steel Drum Closures

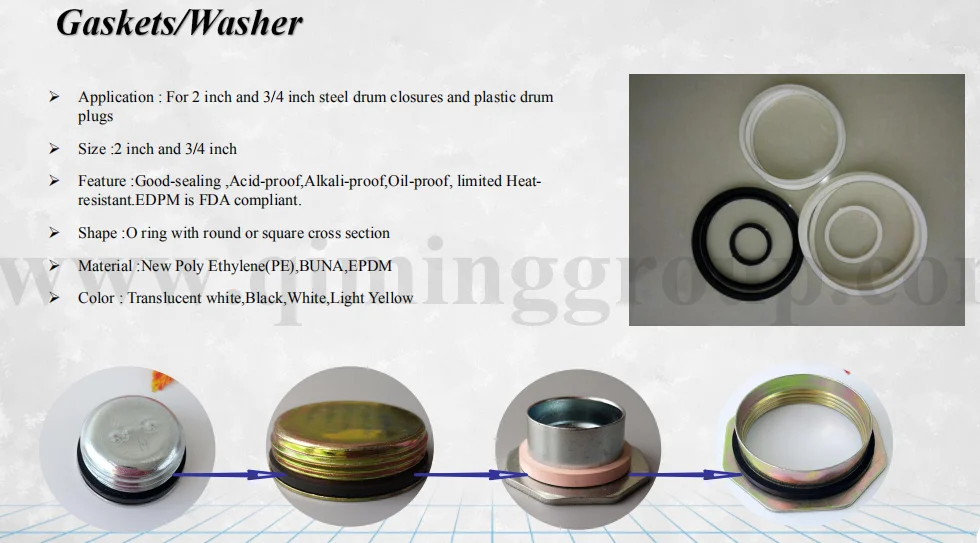

Leak-Proof Design: One of the most crucial features of a steel drum closure is its ability to prevent leaks. This is achieved through precision engineering and the use of high-quality gaskets that create an airtight seal, ensuring that even the most sensitive or hazardous materials remain safely contained.

Tamper-Evident Security: Many industries require drum closures to be tamper-evident to guarantee the safety and integrity of the contents. Steel drum closures can be designed with seals that clearly indicate whether a drum has been opened, providing peace of mind that the product has not been compromised.

Corrosion Resistance: Depending on the stored material, closures may need to resist corrosion from both internal and external factors. High-quality steel and specialized coatings are used to protect against rust, corrosion, and other environmental elements that could otherwise degrade the closure and compromise the drum’s contents.

Easy Application and Removal: While security and protection are paramount, convenience is also a key consideration. Steel drum closures are designed for ease of application and removal, allowing for efficient operations in fast-paced industrial environments.

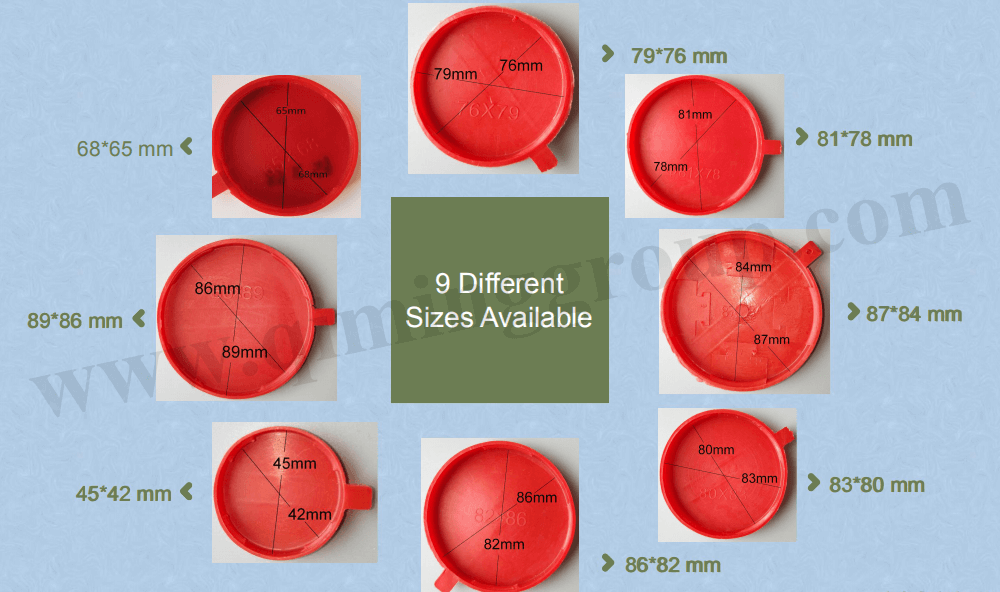

Customizability: Steel drum closures can be customized to meet specific industry needs, whether that’s size, material, or additional features like venting to release internal pressure. This flexibility ensures that each drum closure is perfectly suited to its intended application.

The Importance of Quality Control

Given the critical role that steel drum closures play in industrial storage, ensuring their quality is non-negotiable. Poorly manufactured closures can lead to leaks, contamination, or even accidents, particularly when dealing with hazardous materials. This is why rigorous quality control processes are essential. High-quality closures undergo thorough testing to meet industry standards and regulations, ensuring they provide the protection required in diverse and demanding environments.

Conclusion

Steel drum closures may be small in size, but their impact on industrial storage is immense. By providing leak-proof, tamper-evident, and corrosion-resistant protection, they play a vital role in ensuring the safety and integrity of stored products across various industries. Their versatility, combined with the ability to customize them for specific needs, makes them an indispensable component in any storage solution. When it comes to safeguarding your valuable or sensitive materials, investing in high-quality steel drum closures is not just a good idea—it’s a necessity.

Closures are devices and techniques used to close or seal a bottle, jug, jar, tube, can, etc. Drum closures are used to close and seal the drum or barrel. Closures can be a cap, cover, lid, plug, etc.

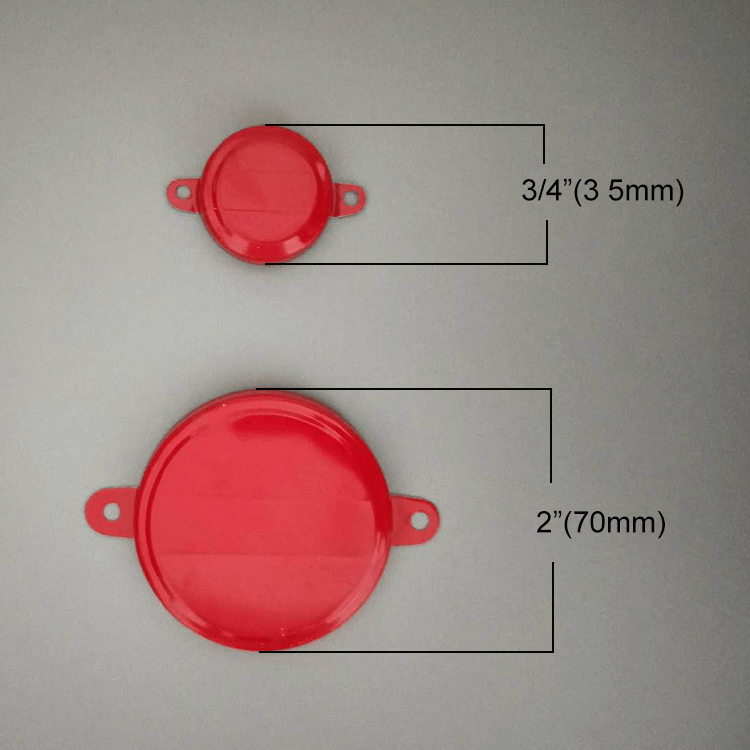

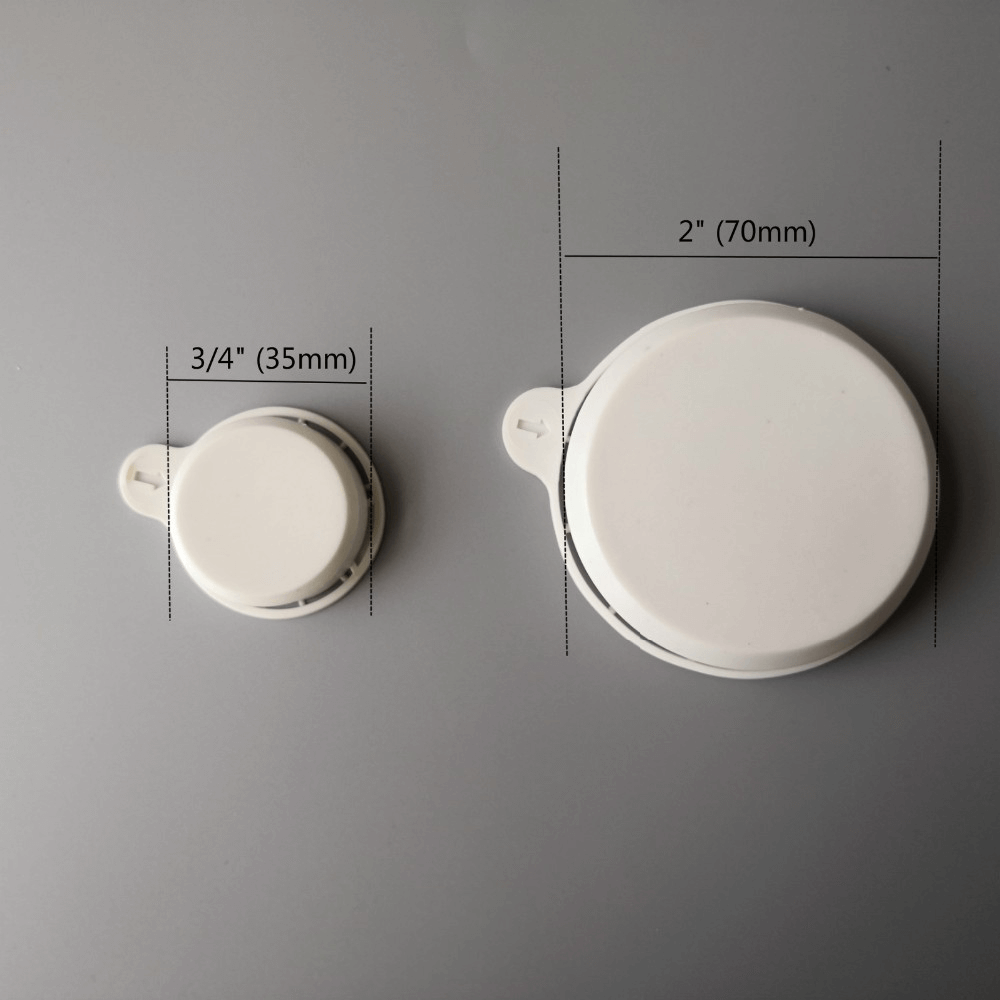

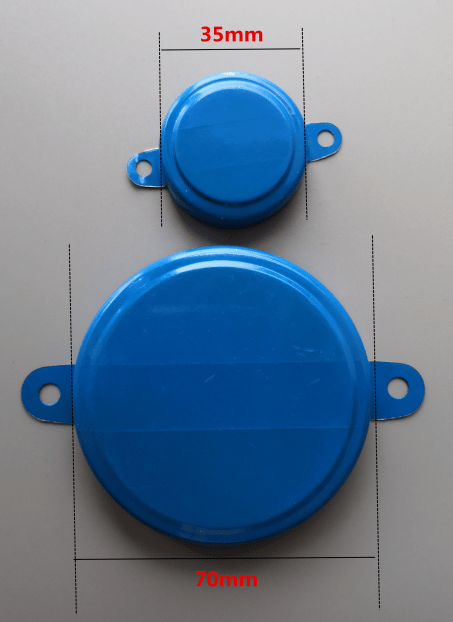

Qiming Packaging one set drum closure include 2 ″ drum flanges +2″ drum plugs+ 3/4 “drum flanges +3/4” drum plugs+ 4 pieces of gaskets.

All the drum closure parts could be sold separately.

Flange type: octagon base; Plug type: round

Plugs bearings NPS and/or BTR threads.

Drum Plug Style: 6 welding points(big) +2 welding points(small)/ 4 welding points(big) +2 welding points(small)

Functions: Good sealing, protecting the drum contents against leaking and contaminating, guaranteeing drum contents original quality.

Free samples available for you for quality checking. Fill in the request free samples form now to get the free samples today.

Note: For drum cap bung seals matched metal drum closures, drum bungs,drum flanges,drum cap seals tools ,plastic plugs also available in Qiming Packaging. Do not find your ideal one? Please contact our support team for a better solution. Or write email direct to mail@qiminggroup.com We assure that your any inquiry on our products will arouse our attention soon. Or you chat online with us, we are here 24 H *7 D at your full disposal.

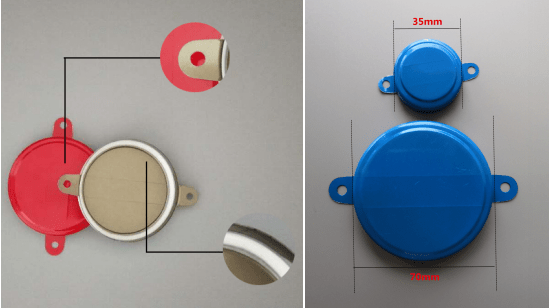

metal drum cap seals for 210 litre drums-Qiming Packaging

metal drum cap seals for 210 litre drums-Qiming Packaging

metal drum cap seals

metal drum cap seals